Traditional PVT and fluid property measurements are often slow, sample-intensive, and logistically complex. In collaboration with industry leaders including ExxonMobil, Chevron, and Equinor through a joint industry project, Interface Fluidics has developed a suite of advanced microfluidic products that deliver faster, more precise, and lower-volume measurements of key reservoir fluid properties. These innovations include Advanced Constant Composition Expansion (CCE) for black oils and retrograde gas condensates, Minimum Miscibility Pressure (MMP) determination, and Oil Swelling measurements—providing critical data in a fraction of the time and with far less sample volume than conventional methods.

Advanced Constant Composition Expansion

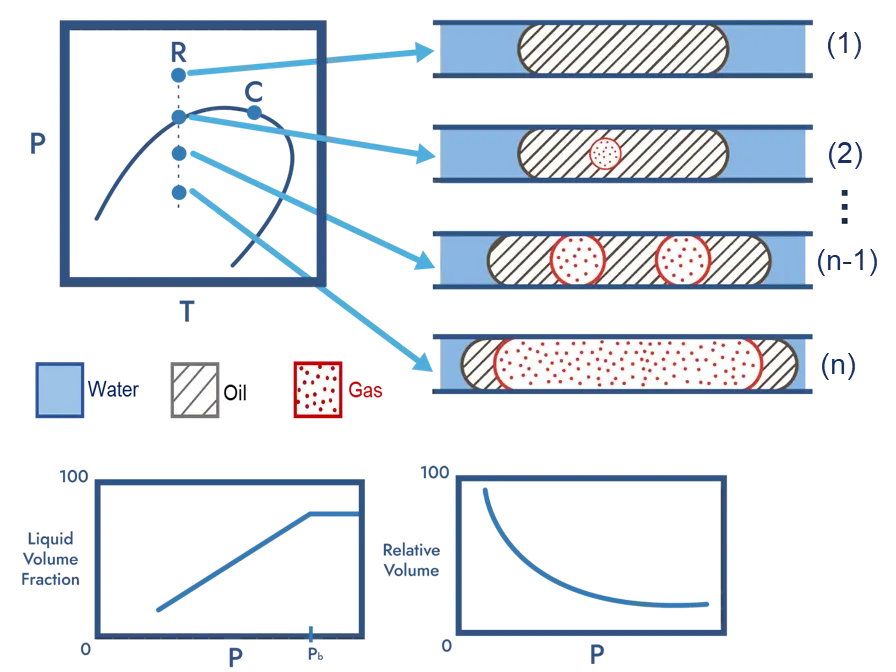

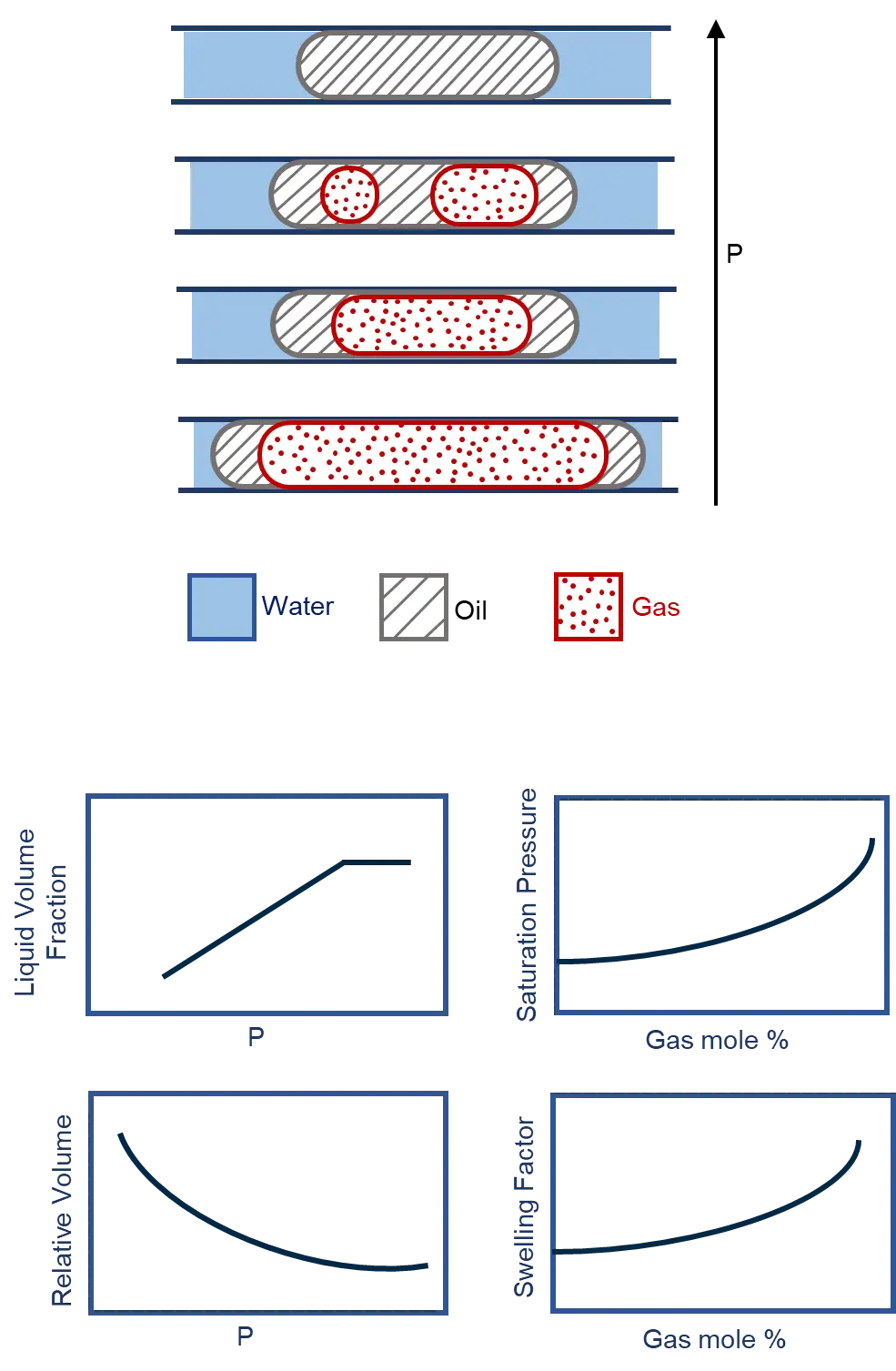

CCE is a laboratory test that measures how reservoir fluid volume changes as pressure decreases under reservoir temperature, while keeping the overall composition constant. It is a critical method for evaluating phase behavior and physical properties of hydrocarbon mixtures.

Key Features of Advanced CCE

- A closed microfluidic channel preserves the initial fluid composition while pressure is stepwise reduced from reservoir conditions.

- Determines the saturation pressure: bubble point for oils and dew point for retrograde gas condensates.

- Provides direct vapor–liquid equilibrium (VLE) measurements through optical access.

- Uses low-volume sensors above saturation pressure to capture high-precision density and viscosity data for reservoir modeling.

Applications

- Generate phase diagrams and tune EOS (equation-of-state) models.

- Improve reservoir simulation and production forecasting accuracy.

- Support evaluation of enhanced oil recovery (EOR) methods and gas injection strategies.

Minimum Miscibility Pressure

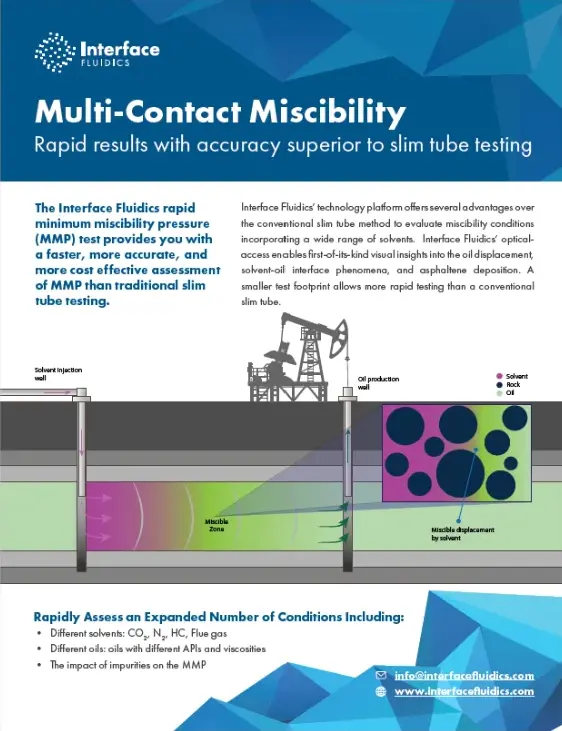

MMP is the lowest pressure at which an injected gas (e.g., CO₂, N₂, or hydrocarbon gas) becomes fully miscible with reservoir oil at reservoir temperature, eliminating the interface between the two phases. At or above this pressure, the injected gas and oil merge into a single phase, significantly improving displacement efficiency and recovery.

Key Features of MMP

- Traditionally measured using high-pressure PVT cells or slim-tube apparatus.

- Slim-tube tests are accurate but require large sample volumes and long testing times.

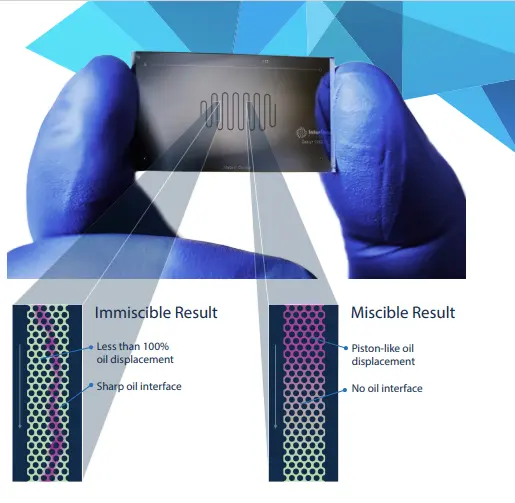

- Microfluidic methods achieve the same measurements much faster and with minimal fluid volumes.

- Direct optical visualization captures the transition from immiscibility to miscibility without relying on data interpolation.

Applications

- Optimize gas injection projects for Enhanced Oil Recovery (EOR).

- Provide critical tuning parameters for EOS models in reservoir simulation.

- Evaluate CO₂ and gas storage efficiency by identifying pressures at which miscibility alters flow pathways.

Oil Swelling

Oil swelling measurement evaluates how reservoir oil volume changes when contacted with an injected gas (e.g., CO₂, hydrocarbon gas, or flue gas) under reservoir temperature and pressure. As gas dissolves into crude oil, it expands the oil volume (swelling effect) and reduces viscosity, both of which improve recovery efficiency in gas injection processes.

Key Features of Oil Swelling

- Traditionally measured in high-pressure PVT cells by injecting gas into a live or recombined crude oil sample.

- Conventional tests provide valuable data but require large sample volumes and long equilibration times.

- Microfluidic methods achieve the same results with smaller samples and enable direct visualization of oil–gas interactions.

- Rapidly captures swelling behavior and corresponding changes in saturation pressure and phase volumes.

Applications

- Assess candidate gases for Enhanced Oil Recovery (EOR) by quantifying swelling data.

- Supply critical input for reservoir simulation, EOS tuning, and gas injection design.

- Support CO₂ utilization and storage by measuring the dual benefit of recovery improvement and CO₂ sequestration.

Case Studies

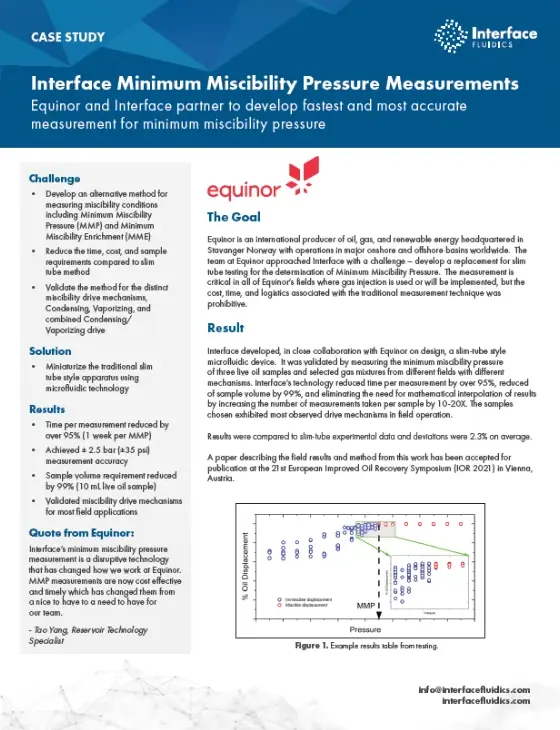

Equinor

Equinor is an international producer of oil, gas, and renewable energy headquartered in Stavanger Norway with operations in major onshore and offshore basins worldwide. The team at Equinor approached Interface with a challenge – develop a replacement for slim tube testing for the determination of Minimum Miscibility Pressure. The measurement is critical in all of Equinor’s fields where gas injection is used or will be implemented, but the cost, time, and logistics associated with the traditional measurement technique was prohibitive.

Broshures

Minimum Miscibility Pressure (MMP)

Interface Fluidics’ technology platform offers several advantages over the conventional slim tube method to evaluate miscibility conditions incorporating a wide range of solvents. Interface Fluidics’ opticalaccess enables first-of-its-kind visual insights into the oil displacement, solvent-oil interface phenomena, and asphaltene deposition. A smaller test footprint allows more rapid testing than a conventional slim tube.

Papers

Microfluidic Constant Composition Expansion for Black Oils and Retrograde Gas Condensates

Sourabh Ahitan, Ali Abedini, Josh Genereux, Taylor Latorre, John Ratulowski, Zhidong Li, Edward C. Wanat, Hussein Alboudwarej, Jon Burger, Frode Ungar, Tao Yang

SPE-214948-PA • December 2024

Building a robust pressure/volume/temperature (PVT) model critically relies on accurate phase behavior data, traditionally obtained using PVT cells. While the PVT cell can provide accurate data, it requires a large volume of downhole or recombined samples, which are usually expensive to collect or time-consuming to create. A novel microfluidic chip design and method are presented in this work to rapidly measure saturation pressure, relative volume, and liquid volume percentages of black oils and retrograde gas condensates (RGCs).

A Novel Method to Measure the Phase Behavior of Black Oils: Saturation Pressure and Liquid-Vapor Fractions

S. Ahitan, A. Abedini, and T. Latorre, Interface Fluidics Ltd., Calgary, Canada; E. Wanat, Z. Li, and M. Velasquez,ExxonMobil, Houston, USA; H. Alboudwarej and J. Burger, Chevron Technical Center, a division of Chevron U.S.A.Inc., Houston, USA; F. Ungar and T. Yang, Equinor ASA, Stavanger, Norway

SPE-214948-MS • October 2023

Building a robust PVT model critically relies on accurate phase behavior data which has been traditionally obtained using PVT cells. While the PVT cell can provide accurate data, it requires a large volume of downhole or recombined samples which are usually expensive to collect. A novel microfluidic chip design and method is presented in this work to rapidly measure bubble point and liquid-vapor volume fractions of black oil systems at multiple pressures and temperatures.

A new fluidics method to determine minimum miscibility pressure

Frode Ungar, Sourabh Ahitan, Shawn Worthing, Ali Abedini, Knut Uleberg, Tao Yang

Journal of Petroleum Science and Engineering, Volume 208, Part B, 209415 • January 2022

Micro and nano-fluidic devices have attracted increasing attention in the oil industry. In this study, we designed a new slim-tube method to determine MMP on a microfluidic chip. The design is significantly different from previous efforts on fluidics chips with an open flowing tube. The new design contains porous media similar to that found in the slim-tube apparatus. The objective is to produce a true multi-contact process in the gas displacement. We tested the new fluidics device at reservoir conditions with three reservoir oils displaced by two hydrocarbon gases and CO2 gas.

Large-Scale High-Throughput Sensitivity Analysis of CO2 MMP to Optimize Gas Injection EOR Processes

A. Abedini, Z. Qi, T. de Haas, and D. O’Brian, Interface Fluidics Ltd., Calgary, Alberta, Canada

SPE-216683-MS • October 2023

Performance of CO2 injection relies on accurate CO2 MMP/miscibility data at reservoir conditions. The CO2 stream typically contains gas impurities, and in most cases CO2 is combined with recycled gasses, which in either case the MMP changes – imposing additional uncertainties to deviate from expected CO2-MMP. Slim-tube is the most reliable tool; however, it is very time- and capital-intensive, making it impossible to provide high-throughput data to assess the impact of other gasses.

A Novel On-Chip Oil Swelling Measurement Platform for Gas Injection EOR Processes

Z. Barikbin, S. Ahitan, J. Genereux, and A. Abedini, Interface Fluidics Ltd., Calgary, Canada; F. Ungar and T. Yang,Equinor ASA, Stavanger, Norway; E. Wanat and Z. Li, ExxonMobil, Houston, USA; H. Alboudwarej and J. Burger,Chevron Technical Center, a division of Chevron U.S.A. Inc., Houston, USA

SPE-218253-MS • April 2024

Oil swelling test data is essential to tune the EOS models to simulate gas injection EOR processes and evaluate the reservoir-scale recovery performances. PVT cells are typically used to measure this property; however, it may involve some challenges with runtime, fluid handling, and test operations. Here, a high-pressure high-temperature microfluidic approach is developed to measure the oil swelling in response to gas exposure under step-wise increasing pressure with different injection gas mole fractions.

Videos

Minimum Miscibility Pressure Testing Capabilities

At Interface Fluidics, we've created a novel microfluidic chip capable of measuring the minimum miscibility pressures of gas-oil systems with greater precision and confidence than the standard slim-tube method.

Microfluidics in Oil & Gas: Minimum Miscibility Pressure

Interface Fluidics has developed the first system that can measure MMP in just a week, at reservoir conditions, using just a few mL of live fluid sample. At this webinar, Interface will present the technology that has enabled this breakthrough, the details of our method, and talk about how we are disrupting the industry with this technology.

PVT Reports Demystified - A Conversation Between a Modeler and Experimentalist Corrected

PVT reports are one of the pillars of the Exploration, Development, and Production workflow. With nearly a 100 years of history, methods, assumptions, and unwritten rules baked into every report, how can modern engineers peel back these complexities to get to the most important pieces of data?