Brochures & Product Information

About Interface Fluidics

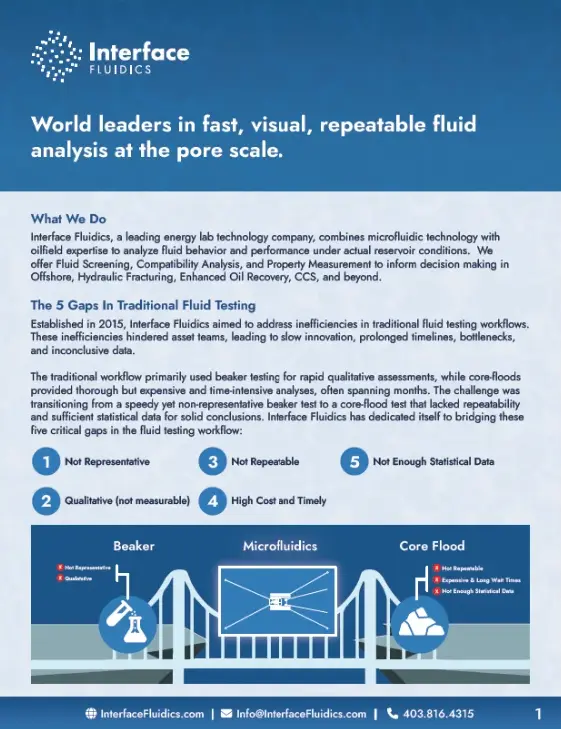

Interface Fluidics, a leading energy lab technology company, combines microfluidic technology with oilfield expertise to analyze fluid behavior and performance under actual reservoir conditions. We offer Fluid Screening, Compatibility Analysis, and Property Measurement to inform decision making in Offshore, Hydraulic Fracturing, Enhanced Oil Recovery, CCS, and beyond.

SapphireLab® Platform

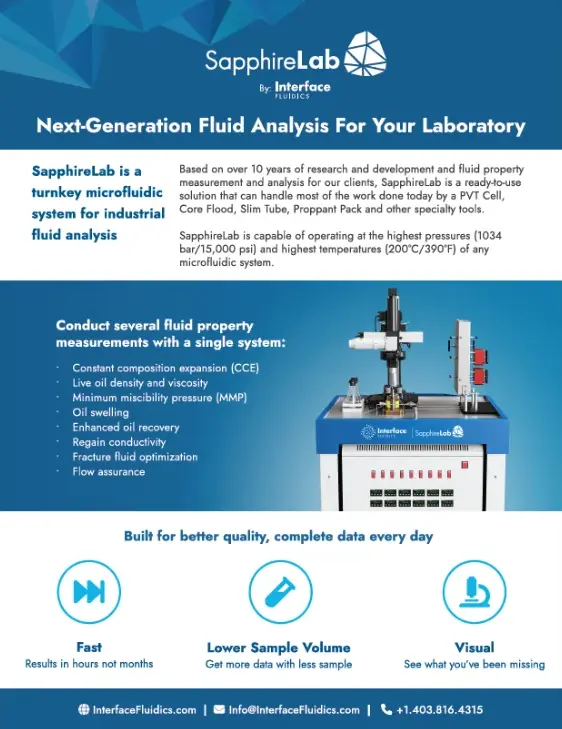

Based on over 10 years of research and development and fluid property measurement and analysis for our clients, SapphireLab® is a ready-to-use solution that can handle most of the work done today by a PVT Cell, Core Flood, Slim Tube, Proppant Pack and other specialty tools.

SapphireLab® is capable of operating at the highest pressures (1034 bar/15,000 psi) and highest temperatures (200°C/390°F) of any microfluidic system.

Enhanced Oil Recovery (EOR)

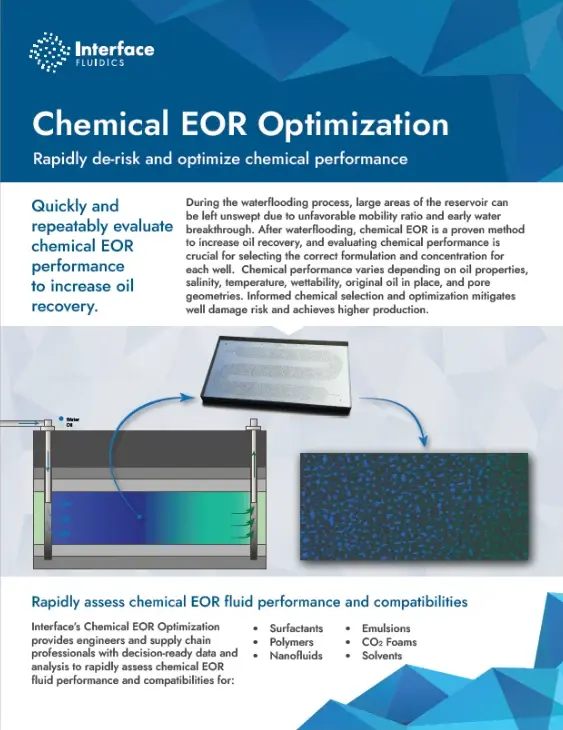

During the waterflooding process, large areas of the reservoir can be left unswept due to unfavorable mobility ratio and early water breakthrough. After waterflooding, chemical EOR is a proven method to increase oil recovery, and evaluating chemical performance is crucial for selecting the correct formulation and concentration for each well. Chemical performance varies depending on oil properties, salinity, temperature, wettability, original oil in place, and pore geometries. Informed chemical selection and optimization mitigates well damage risk and achieves higher production.

Minimum Miscibility Pressure (MMP)

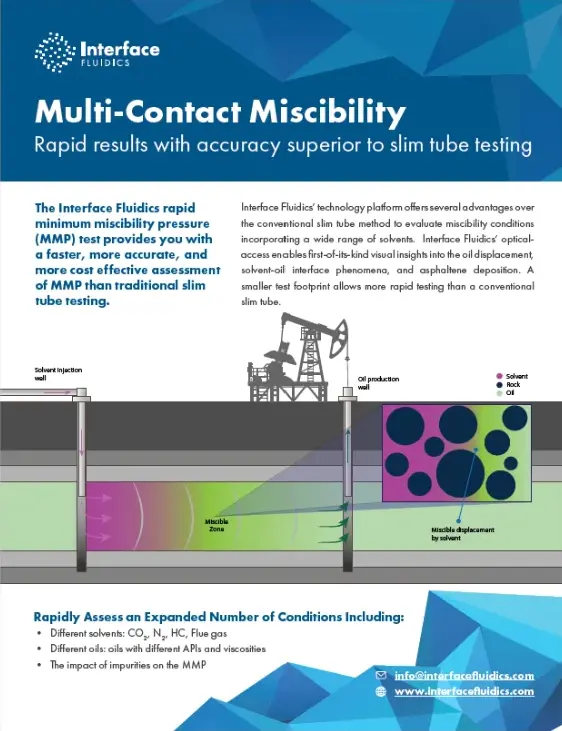

Interface Fluidics’ technology platform offers several advantages over the conventional slim tube method to evaluate miscibility conditions incorporating a wide range of solvents. Interface Fluidics’ opticalaccess enables first-of-its-kind visual insights into the oil displacement, solvent-oil interface phenomena, and asphaltene deposition. A smaller test footprint allows more rapid testing than a conventional slim tube.

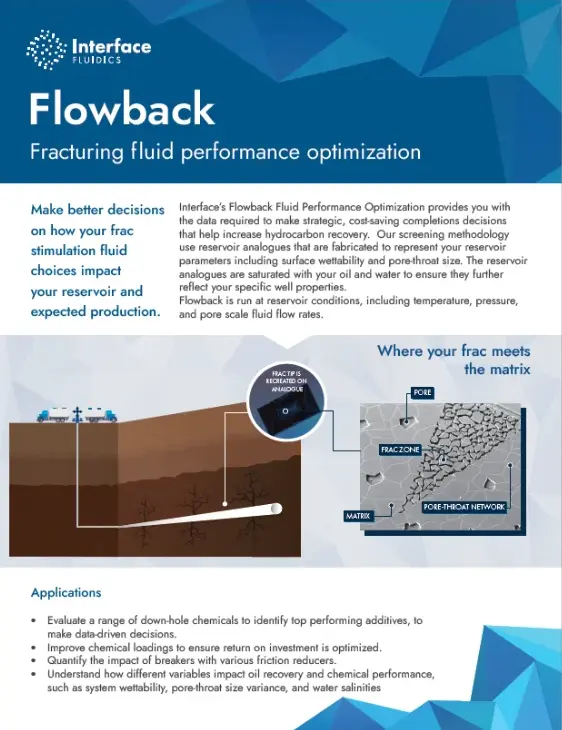

Flowback Analysis

Interface’s Flowback Fluid Performance Optimization provides you with the data required to make strategic, cost-saving completions decisions that help increase hydrocarbon recovery. Our screening methodology use reservoir analogues that are fabricated to represent your reservoir parameters including surface wettability and pore-throat size. The reservoir analogues are saturated with your oil and water to ensure they further reflect your specific well properties. Flowback is run at reservoir conditions, including temperature, pressure, and pore scale fluid flow rates.

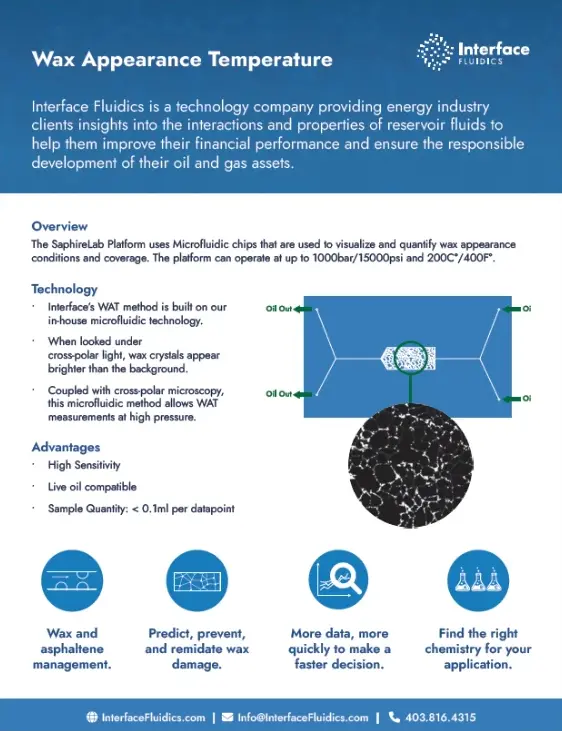

Wax Management

The SaphireLab Platform uses Microfluidic chips that are used to visualize and quantify wax appearance conditions and coverage. The platform can operate at up to 1000bar/15000psi and 200C°/400F°.

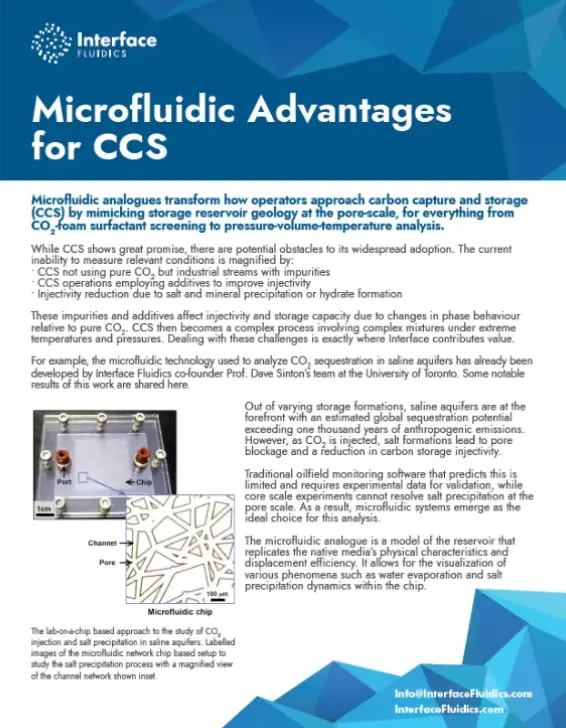

Carbon Capture & Storage (CCS)

Microfluidic analogues transform how operators approach carbon capture and storage (CCS) by mimicking storage reservoir geology at the pore-scale, for everything from CO2-foam surfactant screening to pressure-volume-temperature analysis

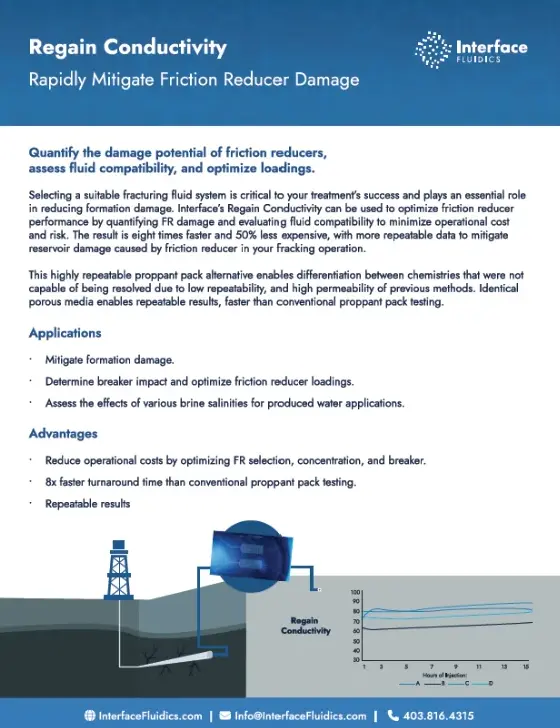

Regain Permeability

Selecting a suitable fracturing fluid system is critical to your treatment's success and plays an essential role in reducing formation damage. Interface's Regain Conductivity can be used to optimize friction reducer performance by quantifying FR damage and evaluating fluid compatibility to minimize operational cost and risk. The result is eight times faster and 50% less expensive, with more repeatable data to mitigate reservoir damage caused by friction reducer in your fracking operation.

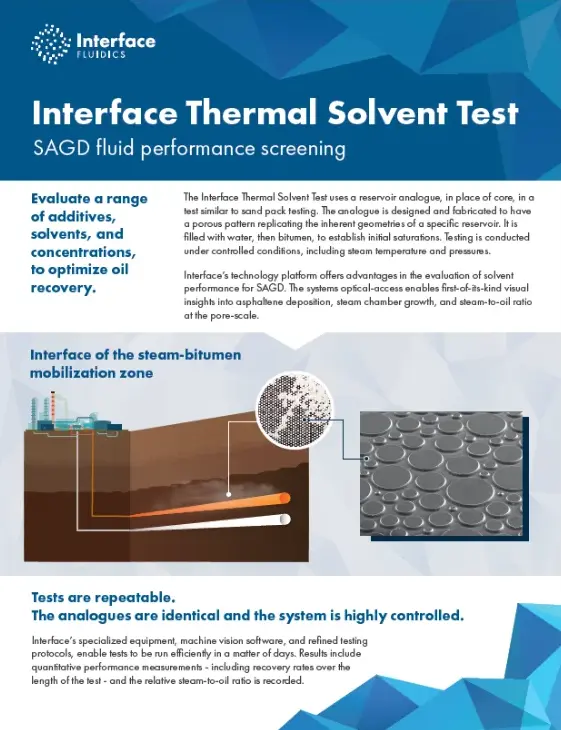

Thermal Solvent Testing

The Interface Thermal Solvent Test uses a reservoir analogue, in place of core, in a test similar to sand pack testing. The analogue is designed and fabricated to have a porous pattern replicating the inherent geometries of a specific reservoir. It is filled with water, then bitumen, to establish initial saturations. Testing is conducted under controlled conditions, including steam temperature and pressures.

Interface’s technology platform offers advantages in the evaluation of solvent performance for SAGD. The systems optical-access enables first-of-its-kind visual insights into asphaltene deposition, steam chamber growth, and steam-to-oil ratio at the pore-scale

Unconventional Resources

Interface Fluidics is the leading provider of strategic and cost-saving solutions to the unconventional oil and gas industry. With 10+ years of experience and more than 100+ successful projects completed around the world, our team works closely with operators, engineers, managers, chemistry suppliers and researchers to solve complex problems and de-risk their operations with unconventional resource development.

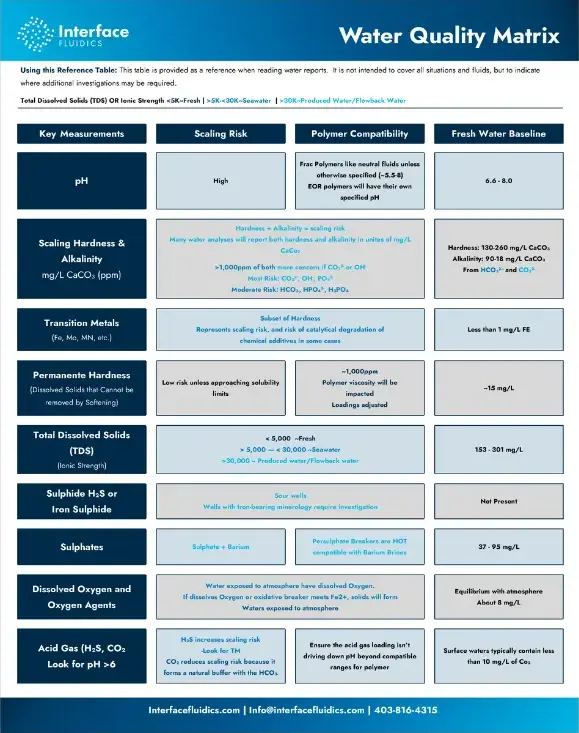

Water Quality Matrix

Comprehensive water quality testing and analysis for oilfield applications