Quality

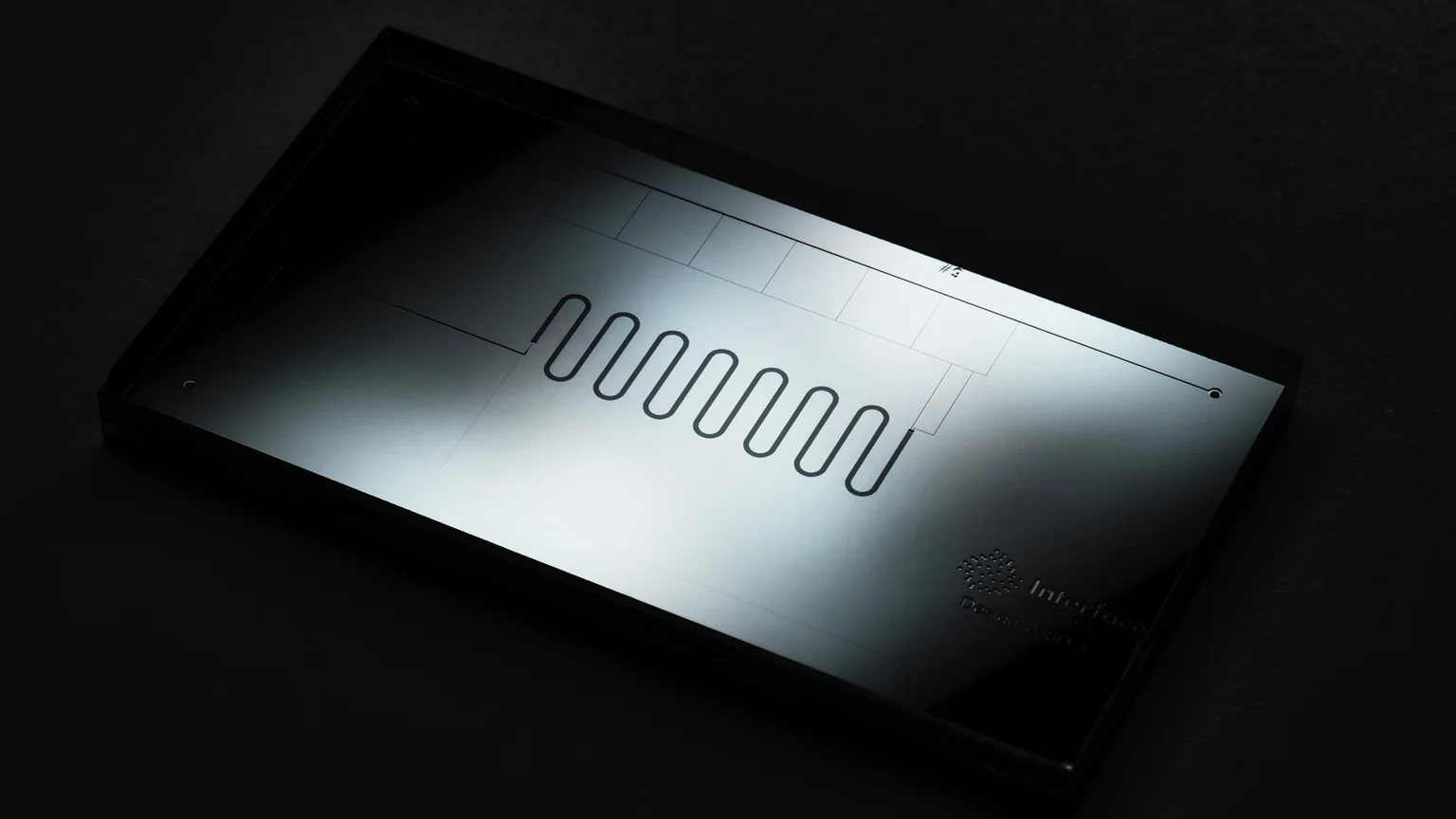

Quality is top of mind throughout the chip fabrication process. Interface Fluidics monitors fabrication quality throughout the fabrication process. Each chip depth is characterized with optical profilometry and the data is mapped against the unique chip identifier stored in the QR code found on the back of every Interface Fluidics Chip.

All microfluidic chips produced by Interface undergo a thorough visual inspection. Only chips that do not have fabrication defects pass through to our customers. In addition to visual inspection, multiple chips per wafer are pressure tested to failure to ensure that they meet specifications.

High-Pressure

SapphireLab® microfluidic chips hold pressure through two means: the structural integrity of the chip and the use of liquid confinement. The chips can hold pressures of up to 2,200 psi (150 bar) by themselves due to the robust silicon/glass construction. If higher pressures are required, our liquid confined chip holder can bring the on-chip pressure to 15,000 psi (1000 bar).

Flexible Design

Interface Fluidics chips are all fabricated on the SapphireLab® chip format 0.85” x 1.5” (21.6 mm x 38.1 mm). We offer chips in both a 4-port and 6-port configuration. The 6-port configuration is only compatible with our liquid confined chip holder.

Nanoscale Features

Interface Fluidics fabricates microfluidic chips with feature widths as small as 2 microns and depths as shallow as 80 nm. These nano-scale features are essential for recreating the nano-confinement found in shale rock and for controlling the flowrate of high-pressure gas.

Custom Microfluidic Solutions

Design custom microfluidic devices tailored to your specific research needs. Our engineering team works with you to create chips that precisely match your experimental requirements.