Enhanced Oil Recovery testing provides critical insights into how different injection strategies impact oil production performance at the pore scale. By replicating reservoir conditions within custom-designed microfluidic systems, a wide range of EOR methods can be evaluated quickly and with unmatched visualization capabilities.

Key Features of EOR Testing

- Comprehensive testing portfolio, including waterflooding optimization, polymer flooding evaluation and optimization, foam rheology testing and optimization, and compatibility testing for injected fluids.

- Customizable porous media designs that replicate reservoir rock properties, generated with Interface Fluidics’ proprietary AI-based porous media generator for high-fidelity modeling.

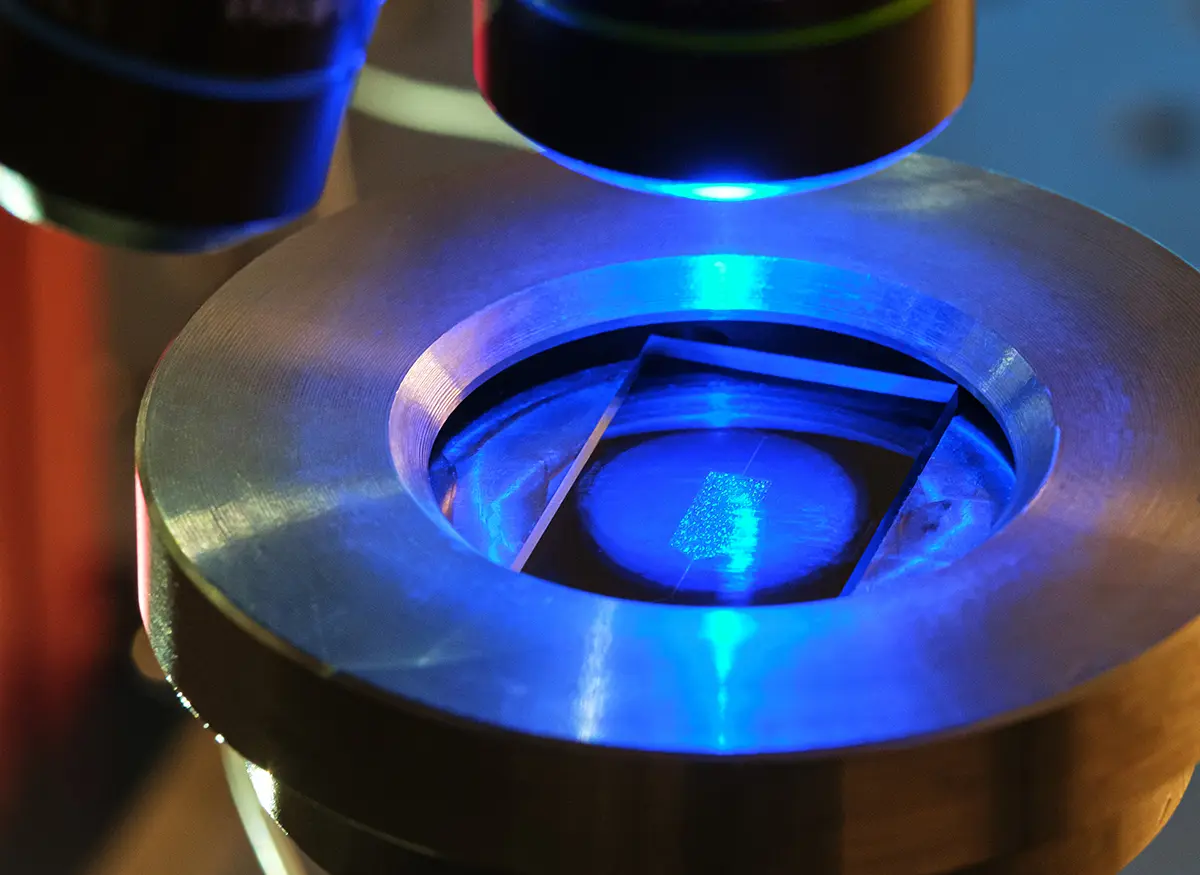

- Direct optical access into the pore space to visualize displacement efficiency, trapping mechanisms, and potential formation damage in real time.

Deliverables

- Quantified oil recovery factor for each EOR method tested.

- High-resolution visualization of pore-scale displacement and trapping phenomena.

- Identification of potential compatibility issues and damage mechanisms under reservoir conditions.

Applications

- Select and optimize the type and loading of chemicals (e.g., polymers, surfactants, foams) for maximum efficiency.

- Design and adjust water composition to minimize scaling, incompatibility, and reservoir damage.

- Reduce operational risk by identifying challenges before field implementation.

- Improve overall project economics through faster screening and optimization of EOR strategies.

Brochure

EOR Optimization

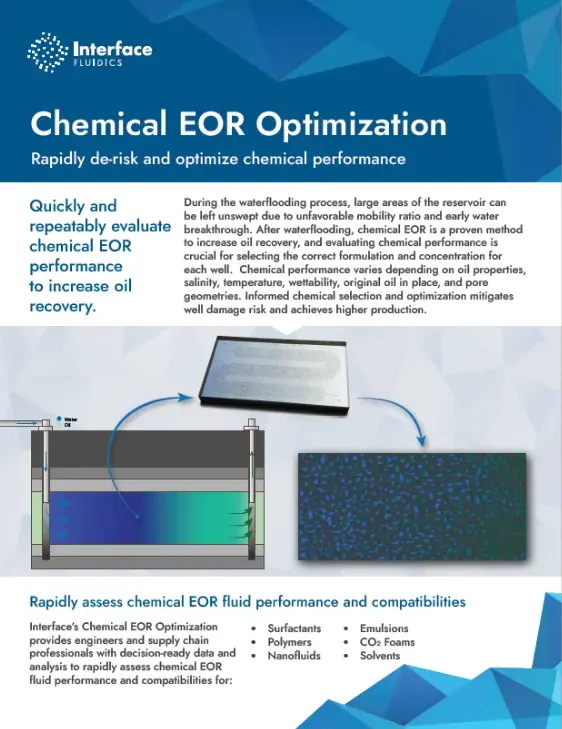

Quickly and repeatedly evaluate chemical EOR performance to increase oil recovery. Interface’s Chemical EOR Optimization uses reservoir analogues designed and fabricated to be representative of each reservoir’s unique properties including pore geometries, permeability, and porosity. This methodology replicates your reservoir attributes, your reservoir fluids and your EOR procedures and approach. Find out more in our brochure at the link below.

Papers

Microfluidic-Based Optimization of Polymer flooding for Heavy Oil Recovery

Zhenbang Qi, Xingyu Fan, and Ali Abedini, Interface Fluidics Limited; Duilio Raffa, Baytex Energy Corp

SPE-212758-MS • March 2023

Polymer flooding has been implemented in Western Canada, specifically in Saskatchewan and Alberta since 2000s. Flooding with polymer has been more effective than with water in heavy oil reservoirs due to a more favorable mobility ratio, resulting in more a stable front and less fingering. Optimization of polymer flood strategies is essential for successful implementation of field-scale operations. Core and sand-pack flood testing have been a reliable method for laboratory evaluation of different injection methods and chemicals as the cores are representative of the reservoir geometries and rock chemistries.

Microfluidic Pore-scale Analysis of Polymer Flooding Effects of Polymer Molecular Weight and Viscosity

Z. Qi, X. Fan, O. Serediak, A. Abedini, P. Ghosh and R. Wilton

Second EAGE Workshop on EOR in Latin America, Volume 2022, p.1 – 7 • October 2022

Polymer flooding is a widely applied EOR method to increase oil recovery from heavy oil reservoirs by improving the mobility and conformance control of the displacement process. Core and sandpack floodings have been mostly applied to evaluate the polymer flooding performance for a given reservoir; but the associated pore-scale dynamics with varying polymer MW and chemistry remains unclear in these experiments. Hence, a synergistic approach of coreflood testing along with visual experiments can provide the detailed insight of polymer flow behavior and performance.

Effects of thief zones on displacement efficiency: Microfluidic pore-scale

ZhenBang Qi, Scott Pierobon, Owen Serediak, Jonathon Le, Adam Pettigrew, Ali Abedini

Fuel Volume 316, 123371 • May 15, 2022

Thief zones are regions with high permeability, usually formed in mature or depleted reservoirs after water flooding, which can further reduce the overall recovery during subsequent EOR stages. While existing conformance control solutions alleviate the impact of thief zones, selecting an optimal solution based on current laboratory methods is challenging, since current methods fail to isolate the impact of thief zones, lack tight control of initial conditions, and use long evaluation times as well as large sample volumes.

A Set of Successful Chemical EOR Trials in Permian Basin: Promising Field and Laboratory Results

Mehrnoosh Moradi Bidhendi, Mahdi Kazempour, Uwana Ibanga, Duy Nguyen, Justin Arruda, Mike Lantz, Cooper Mazon, NALCO Champion, an Ecolab Company

URTEC-2019-881-MS • July 2019

Unconventional liquid reservoirs are currently one of the most important sources of oil in North America. Oil production experiences a rapid decline in these reservoirs and this has been a major issue faced by many operators. Low oil recovery has been attributed to ultralow permeability, low porosity and oil-wet nature of the reservoir rock. Hence, wettability alteration using chemicals could provide a viable chemical enhanced oil recovery method (cEOR) to increase oil production from these reservoirs.

High-temperature high-pressure microfluidic system for rapid screening of superficial CO2 foaming agents

Ayrat Gizzatov, Scott Pierobon, Zuhair AlYousef, Guoqing Jain, Xingyu Fan, Ali Abedini & Amr I. Abdel-fattah

Scientific Reports 11, Article number 3360 • 2021

CO2 foam helps to increase the viscosity of CO2 flood fluid and thus improve the process efficiency of the anthropogenic greenhouse gas’s subsurface utilization and sequestration. Successful CO2 foam formation mandates the development of high-performance chemicals at close to reservoir conditions, which in turn requires extensive laboratory tests and evaluations. This work demonstrates the utilization of a microfluidic reservoir analogue for rapid evaluation and screening of commercial surfactants (i.e., Cocamidopropyl Hydroxysultaine, Lauramidopropyl Betaine, Tallow Amine Ethoxylate, N,N,N′ Trimethyl-N′-Tallow-1,3-diaminopropane, and Sodium Alpha Olefin Sulfonate) based on their performance to produce supercritical CO2 foam at high salinity, temperature, and pressure conditions.

Videos

New Methods for EOR Optimization Using Microfluidics

Interface Fluidics presented their collaboration with two Canadian heavy oil producers on microfluidics-based optimization for heavy oil recovery. They explained in detail how microfluidics can optimize chemical spend and increase oil recovery, drawing on their experience in Alberta and Saskatchewan’s heavy oil fields.

I Can't Believe It's Not Rock! - January 2023 Webinar

Interface Fluidics presents a panel discussion about the different types of fluid testing and the role of core/rock in fluid analysis. As an important player in fluid testing, one of the biggest questions we get from our clients is why we don't use real rock in our systems and how we ensure representative results.

Polymer Enhanced Oil Recovery: Applying Microfluidic Analogue Technology

Part of our mission at Interface is to help make oil recovery more efficient – particularly through enhanced oil recovery. Using our own reservoir-mimicking analogues, polymers and other EOR fluids can be injected under well-specific conditions to evaluate performance. This screening allows for better field decisions to be made by optimizing chemical type, concentration, slug size, injection rate, and more.

Analogue Design for U.S. Reservoirs: Customizing Microfluidic Devices to Optimize Well Performance

Interface designs and fabricates custom reservoir analogues so you can evaluate a range of down-hole chemicals using your specific reservoir characteristics and fluids to identify top performing additives, allowing you to make faster, data-driven decisions.