Flow assurance testing provides critical data on how wax, scale, asphaltenes, and emulsions impact production systems and reservoir performance. Using advanced microfluidic platforms, these challenges can be visualized and quantified at the pore scale, enabling faster screening and optimization of chemical treatments under true reservoir conditions.

Key Features of Flow Assurance Studies

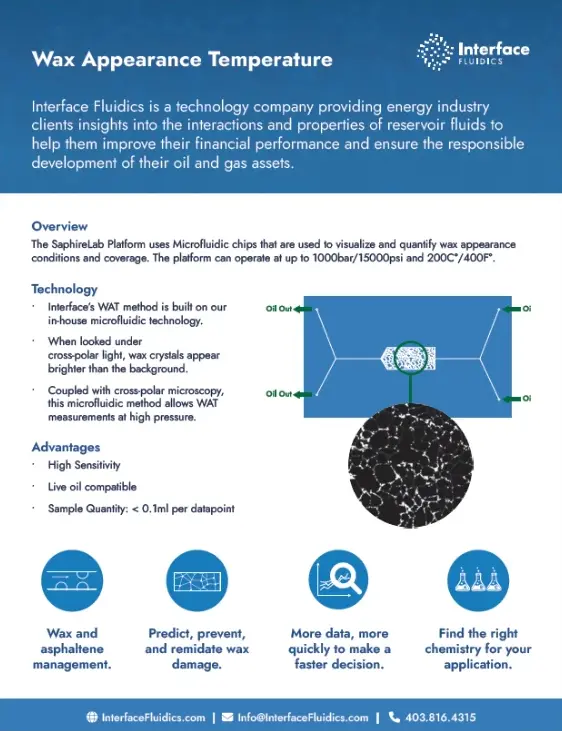

- Wax: Measure wax appearance temperature (WAT), monitor crystal growth dynamics, and evaluate wax inhibitor performance.

- Scale: Conduct scale tendency and compatibility testing, screen scale inhibitors, and assess reservoir impairment caused by scale deposition.

- Emulsions: Characterize emulsification behavior and emulsion stability; evaluate emulsion breakers and de-emulsifiers.

- Asphaltenes: Determine asphaltene onset pressure (AOP), test asphaltene inhibitors, and assess reservoir impairment due to asphaltene precipitation and deposition.

Deliverables

- Quantified onset conditions for wax, scale, emulsions, and asphaltenes.

- Direct optical visualization of deposition, plugging, and emulsion behavior at the pore scale.

- Evaluation of chemical treatment performance under reservoir-representative conditions.

- Identification of potential reservoir and production system impairments linked to flow assurance risks.

Applications

- Optimize selection and dosage of inhibitors, breakers, and treatment chemicals to mitigate flow assurance risks.

- Predict and manage production challenges related to wax, scale, emulsions, and asphaltenes.

- Reduce operational downtime and remediation costs by addressing risks before field deployment.

- Improve overall system reliability and flow efficiency through proactive flow assurance design.

- Evaluate water compatibility challenges for subsurface energy applications, including produced water reinjection and water disposal in emerging sectors such as lithium extraction.

Brochures

Wax Management

The SaphireLab Platform uses Microfluidic chips that are used to visualize and quantify wax appearance conditions and coverage. The platform can operate at up to 1000bar/15000psi and 200C°/400F°.

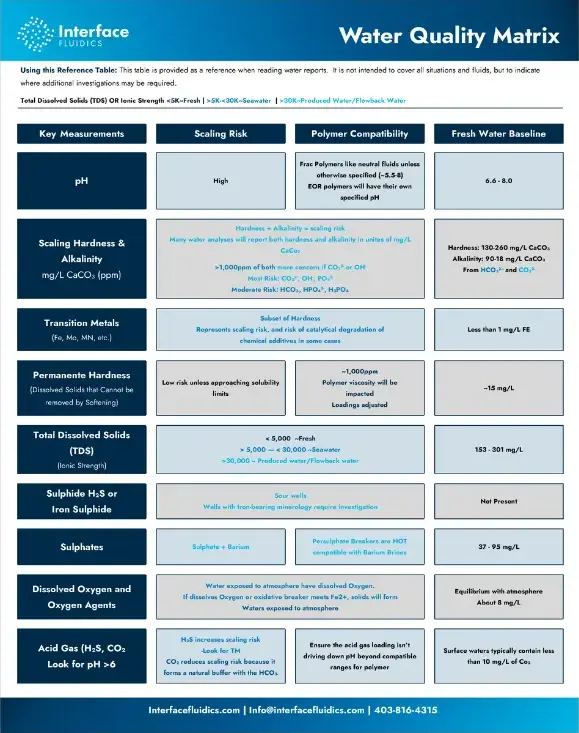

Water Quality Matrix

Comprehensive water quality testing and analysis for oilfield applications

Papers

Microfluidic Pore-scale Analysis of Wax and Scale Formation/Mitigation for Sub-surface Water Injections

Authors M. Yousefi, Z. Qi, A. Meimanova, S. Kinnear, A. Abedini and K. Graham

IOR+ 2025 - 23rd European Symposium on IOR, Apr 2025, Volume 2025, p.1 - 15 • Apr 2025

A North-Sea operator was experiencing low injectivity in a water injection well that was injecting into both the water and oil legs of the formation of interest, potentially due to wax and scale formation under operating conditions. This study was motivated by a desire to confirm wax and scaling tendency, to identify the cause of the individual scaling mechanisms, understand the individual and combined impacts on formation damage, and to evaluate the effectiveness of wax and scale prevention chemicals in mitigating the problem.

Videos

Case Study in Microfluidic Scale and Wax Mitgation in Waterflooding - EAGE IOR+ Re-Broadcast

In this webinar, Interface Fluidics team members present work that was originally published at the 2025 EAGE IOR+ conference in Edinburgh followed by a panel discussion with the technical team.

Solving Lithium Brine Challenges

Interface FLuidics work with Summit Nanotech to solve lithium brine challenges, findings were discussed at EAGE NSG September 2024.

Produced Water Reuse and Disposal Webinar - November 2022

Hydrocarbon production both uses and produces amazing amounts of water. In the U.S., every barrel of oil has 10 barrels of produced water pumped along with it. Companies are still figuring out how to best utilize this supply.

Wax Mitigation and Remediation: A Microfluidic Approach

Wax deposition is one of the oldest problems facing oil transport. It can lead to decreased flow rates, an increase in required pumping power, or even equipment failure.