Case Studies

Baytex Energy

Baytex Energy, a North American oil producer headquartered in Calgary, Alberta, focuses on crude oil and natural gas production in the Western Canadian Sedimentary Basin and the Eagle Ford in the United States. Baytex approached Interface Fluidics because they had been conducting a tertiary polymer flood in their Lloydminster sandstone formation since 2018. Baytex were seeking a test that could accurately predict incremental oil and water rates and the ultimate recovery factor to de-risk a polymer reduction and a change of polymer suppliers.

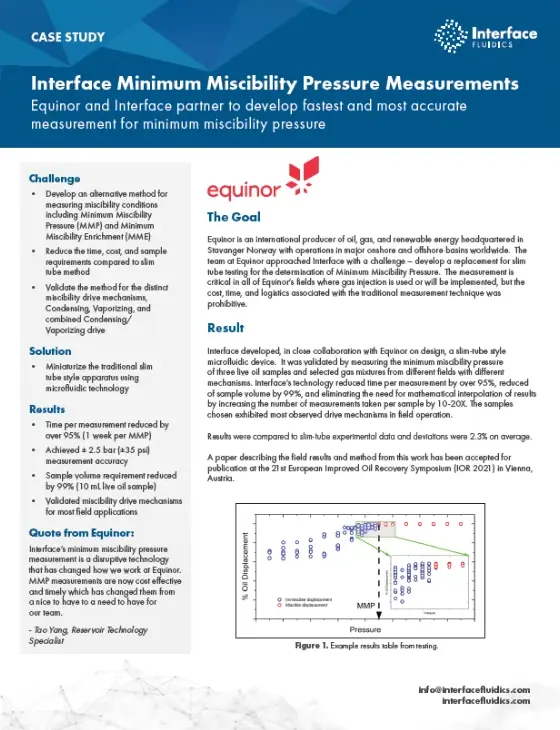

Equinor

Equinor is an international producer of oil, gas, and renewable energy headquartered in Stavanger Norway with operations in major onshore and offshore basins worldwide. The team at Equinor approached Interface with a challenge – develop a replacement for slim tube testing for the determination of Minimum Miscibility Pressure. The measurement is critical in all of Equinor’s fields where gas injection is used or will be implemented, but the cost, time, and logistics associated with the traditional measurement technique was prohibitive.

Ovintiv

Ovintiv is a leading North American energy producer keen on driving innovation within industry. Quantifying friction reducer performance is a necessary part of Ovintiv’s workflow, playing an essential role in reducing formation damage and optimizing flowback. Together, Ovintiv and Interface recognized an opportunity to address the technical challenges, such as high variability, and the inefficiencies associated with proppant pack testing using Interface’s microfluidic technology. A solution was found that reduced cost and time while increasing run-to-run repeatability, realizing a step change in how friction reducers are evaluated, with the potential to revolutionize the formation damage measurement industry.

Primexx Operating Partners

Primexx Energy Partners Ltd. (Primexx), a technology focused oil-and-gas exploration and production company operating in the Southern Delaware Basin of West Texas, approached Interface to ensure they were using the most cost effective and highest performing chemical additives in their fracturing operations. Interface screened seven products from five vendors. Through Interface’s screening process, Primexx was able to qualify a new vendor, reduce chemical loadings by 3x from previous wells without impacting initial production, and achieved a chemical cost savings of over 50% compared to their prior well fracturing program.

Rapid Evaluation of Eagle Ford Flowback

Microfluidics - when adapted for oil and gas - is a technology that helps the energy industry evaluate an array of stimulation products and their compatibility with individual reservoirs for specific applications down-hole. This paper outlines the benefits of microfluidics analysis, how a large multinational operator applied it, and how it impacted decisions being made in the field

Select Chemistry Optimization

Select Chemistry, a chemical and logistics solutions provider in the United States, has a unique understanding of the specialized needs of its clients. The company offers a wide range of products for well completion and stimulation, with targeted research and expertise to ensure the best product reaches the market. Part of the evaluation that goes into launching a new product – or optimizing an existing one – is to quantify and mitigate friction reducer damage.

Sval Energi

Sval Energi, a exploration and production company that produces oil and gas from the Norwegian Continental Shelf, encountered significant challenges with lower-than-expected injectivity during cold seawater injection into a hot paraffinic oil reservoir. This issue was critical, directly affecting their ability to maintain efficient oil recovery. Wax and scale deposition were identified as possible contributors to formation damage, reduced injectivity, and diminished oil recovery rates. Sval Energi sought to quantify the individual impact of wax and scale on injectivity decline and evaluate the effectiveness of inhibitor treatments in mitigating these issues.