Fluid compatibility is often the difference between a high-performing well and a costly production issue. Even when chemistry remains consistent, formation water and hydrocarbons vary well to well or pad to pad.

Getting the right fluids and doses is critical for success—but traditional shale fluid analysis faces major challenges:

- Speed: Amott Cell tests can take weeks to months

- Consistency: Variations between shale cores make comparisons unreliable

- Accuracy: Core flood setups struggle with low-effluent conditions, leading to errors and delays

The SapphireLab® Flowback Test provides a fast, standardized method to screen individual chemistries or complete fracturing fluid packages. In a single run, it identifies potential compatibility issues, measures hydrocarbon production, and visualizes formation damage, all while using consistent porous media for reliable side-by-side comparisons.

Key Features

- Rapid compatibility testing of fracturing fluids with hydrocarbons and brines

- Direct visualization of damage mechanisms and productivity impacts

- Optimization of additive packages to minimize risks and maximize recovery

Applications

- Accelerate fluid package testing and optimization with results in under a day

- Reduce startup and production challenges, enabling faster, more reliable well performance

- Predict, prevent, and remediate issues such as scale formation or chemical degradation under reservoir conditions

Fracturing Fluids Optimization

Fracturing Fluids Optimization using SapphireLab® Flowback technology and analysis of results.

Why The SapphireLab® Flowback Test is superior

Completions Engineers

Prevent Overspending on Chemistry

When it comes to surfactants and flowback aids, using more than the optimal dosage can diminish the ability of oil to flow from formations. In addition to selecting the correct concentration of a flowback aid, the SapphireLab® Flowback test can provide insight into the fluids package to ensure that there are no chemical-chemical or chemical-water incompatibilities by testing whole fluid systems, in addition to testing components in isolation.

Completions Engineers

Reduce Formation Damage

The SapphireLab® Flowback test enables rapid screening of hydraulic fracturing fluid packages to minimize formation damage. Teams can optimize oils, surfactants, polymers, and water sources at extreme conditions, testing different chemistries at low cost and zero risk. The best performing packages can be validated in core floods before field deployment, resulting in better performing wells with reduced formation damage.

Fluid Providers

Optimize Fluid Packages for Customer Projects

Because we can accurately manufacture many microfluidic chips with the same specifications, and the SapphireLab® Flowback test can typically be performed in a day, it is both convenient and possible to screen frac fluid packages to pick the best performer for a given reservoir.

Fluid Providers

Accelerate New Product Development

The development and fine tuning of new chemical formulations takes time, some trial and error, and deep insight into fluid compatibility and behavior. The inherent speed and repeatability of the Flowback test makes it a perfect match for experimentation and fluid formulation development, for quick turnarounds.

Fluid Providers

Gain Competitive Advantage

Gain a competitive advantage by clearly demonstrating to your customers the effectiveness of your chemistries in combination with other injected and reservoir fluids.

Service Laboratories

Accelerate Project Delivery

With tests completed in about a day, the SapphireLab® Flowback test significantly accelerates project timelines for routine fluid screening, core floods, and R&D projects. Its high throughput and low resource requirements make it ideal as a pre-core flood screening tool, optimizing the use of valuable core and fluid samples while delivering faster results to clients.

Service Laboratories

Add New Capabilities

The SapphireLab® Flowback test offers Service teams a new tool to rapidly screen fluids for customer projects. This test can be a precursor test to traditional core floods, or stand alone by enabling comparisons of full frac fluid packages never before possible.

Comparison With Traditional Test Methods

| SapphireLab® Flowback | Proppant Pack | Core Flood | Amott Cell | |

|---|---|---|---|---|

| Can predict the relative performance of volume of oil flowed back | ✓ | ✓ | ✓ | ◐ |

| Conducted at high pressure and high temperature | ✓ | ✓ | ✓ | × |

| Does not require cuttings or core | ✓ | ✓ | × | × |

| Can be run in a day | ✓ | × | × | × |

| Tests use consistent porous media | ✓ | × | × | × |

| Enables visualization of formation damage and pore scale fluid flow | ✓ | × | × | × |

| Designed for low fluid flow rates and volumes | ✓ | × | × | × |

Can predict the relative performance of volume of oil flowed back

Conducted at high pressure and high temperature

Does not require cuttings or core

Can be run in a day

Tests use consistent porous media

Enables visualization of formation damage and pore scale fluid flow

Designed for low fluid flow rates and volumes

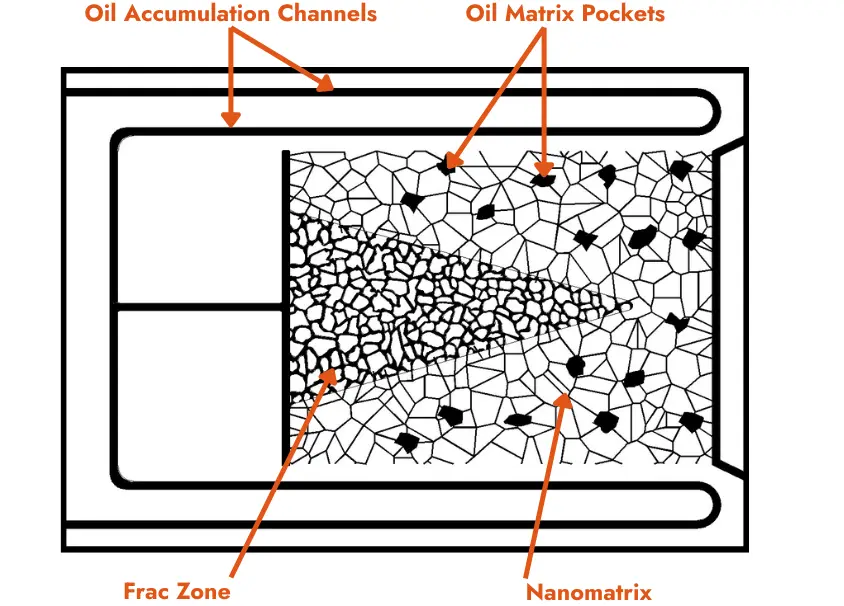

How it Works

The SapphireLab® Flowback test uses microfluidics technology to help you analyze fluid interactions at high pressure and high temperature conditions at the micro and nano scale. Interface Fluidics has leveraged over 15 years of experience and innovation in microfluidic research and development, to produce this standardized test. Since initial development, Interface Fluidics and its customers have successfully ran thousands of Flowback tests, helping producers increase hydrocarbon production, lower fluids expenses and reduce formation damage.

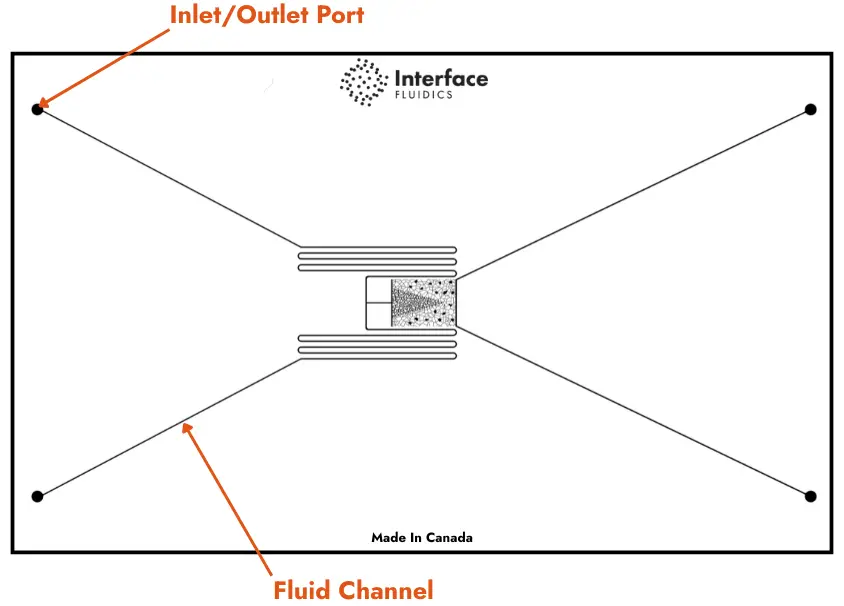

Conducting a Flowback test requires several key components, and can be completed in our laboratory or in your laboratory by purchasing our turnkey SapphireLab® system.

The Flowback S100 Microfluidic Chip

he Flowback S100 Microfluidic Chip

Image above depicts a Flowback S100 Microfluidic Chip

Image above depicts a close up of the porous media on the Flowback S100 Microfluidic Chip

Case Studies

Rapid Evaluation of Eagle Ford Flowback

Microfluidics - when adapted for oil and gas - is a technology that helps the energy industry evaluate an array of stimulation products and their compatibility with individual reservoirs for specific applications down-hole. This paper outlines the benefits of microfluidics analysis, how a large multinational operator applied it, and how it impacted decisions being made in the field

Select Chemistry Optimization

Select Chemistry, a chemical and logistics solutions provider in the United States, has a unique understanding of the specialized needs of its clients. The company offers a wide range of products for well completion and stimulation, with targeted research and expertise to ensure the best product reaches the market. Part of the evaluation that goes into launching a new product – or optimizing an existing one – is to quantify and mitigate friction reducer damage.

Ovintiv

Ovintiv is a leading North American energy producer keen on driving innovation within industry. Quantifying friction reducer performance is a necessary part of Ovintiv’s workflow, playing an essential role in reducing formation damage and optimizing flowback. Together, Ovintiv and Interface recognized an opportunity to address the technical challenges, such as high variability, and the inefficiencies associated with proppant pack testing using Interface’s microfluidic technology. A solution was found that reduced cost and time while increasing run-to-run repeatability, realizing a step change in how friction reducers are evaluated, with the potential to revolutionize the formation damage measurement industry.

Brochures

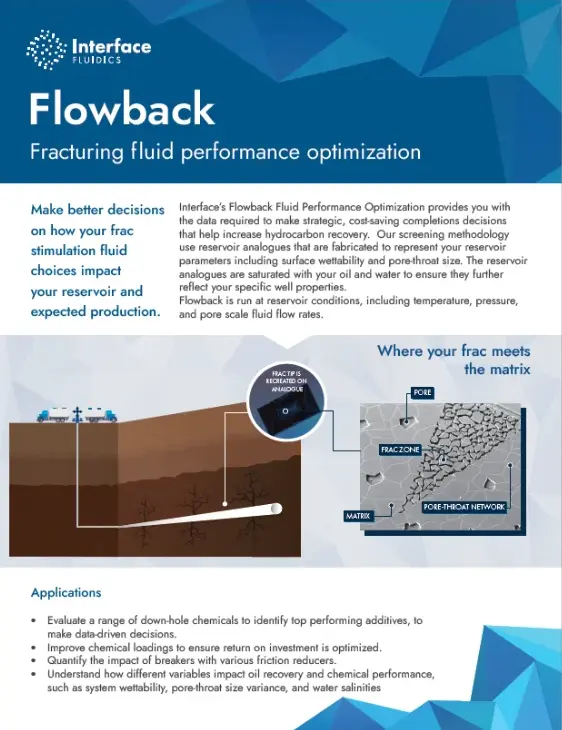

Flowback Analysis

Interface’s Flowback Fluid Performance Optimization provides you with the data required to make strategic, cost-saving completions decisions that help increase hydrocarbon recovery. Our screening methodology use reservoir analogues that are fabricated to represent your reservoir parameters including surface wettability and pore-throat size. The reservoir analogues are saturated with your oil and water to ensure they further reflect your specific well properties. Flowback is run at reservoir conditions, including temperature, pressure, and pore scale fluid flow rates.

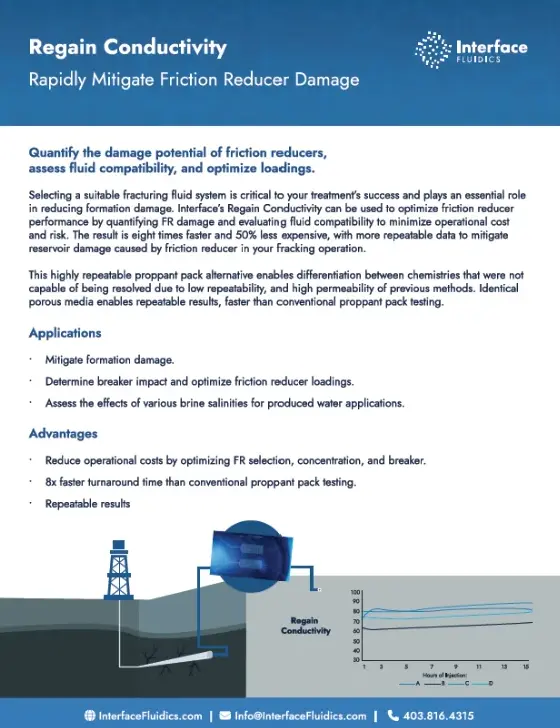

Regain Permeability

Selecting a suitable fracturing fluid system is critical to your treatment's success and plays an essential role in reducing formation damage. Interface's Regain Conductivity can be used to optimize friction reducer performance by quantifying FR damage and evaluating fluid compatibility to minimize operational cost and risk. The result is eight times faster and 50% less expensive, with more repeatable data to mitigate reservoir damage caused by friction reducer in your fracking operation.

Papers

Microfluidics – A New Tool to Differentiate Chemistry for Fracs – Functional Frac Performance Vs Reservoir Performance

S. Liu; Y. Li; A. Abedini

SPE-224229-MS • Apr 2025

Unconventional reservoirs play an important role in the global energy supply nowadays due to recent advancements in hydraulic fracturing. It has been reported that the selection of completion chemicals has a significant impact on oil and gas production due to fluid incompatibility and polymer-induced formation damage. To optimize oil and gas production, flowback efficiency, and fracturing fluid-induced permeability damage, different completion fluid packages were evaluated using microfluidics.

Bioremediation Study on Formation Damage Caused by Hydraulic Fracturing: A Microfluidic Approach

Songyuan Liu, Chao-yu Sie, Fatee Malekahmadi, Bo Lu, and Yifan Li, Rockwater Energy Solutions; Cara Fan,Xinyue Zhang, Owen Serediak, Jelayne Fortin, and Ali Abedini, Interface Fluidics Ltd

SPE-210089-MS • September 2022

Hydraulic fracturing has been applied to unconventional reservoirs with low permeability to achieve higher productivity and economic potential. However, polyacrylamide-based friction reducer and guar gum, two of the most common components in fracturing fluid could cause formation damage by penetrating into the matrix and blocking the flow path. To regain the conductivity of the damaged area, a bioremediation method was developed and validated by a microfluidic approach. Modified nutrients were used to stimulate the indigenous bacteria that could consume or break the polymer residues.

Visualization of Flowback Aid Mechanisms Utilizing a Microfluidic Pore-Scale Device

Ginger Ren, Stepan Oilfield Solutions; Ali Abedini, Interface Fluidics Ltd.; Hyuntae Yang and Aaron Sanders,Stepan Oilfield Solutions

SPE-199269-MS • February 2020

Using flowback additives in slickwater fracturing fluids is a relatively recent innovation, and regained permeability testing using corefloods is the preferred performance evaluation method. The coreflood rig simulates the hydraulic fracturing process by injecting the fracturing fluid through a core under relevant pressure and temperature conditions, and measures the permeability and relative permeability changes during injection. Permeability measurements indicate whether the fracturing fluid damages the formation during hydraulic fracturing that in turn reduces oil productivity during flowback.

Novel Oil Flow Enhancement Chemistry for Unconventional Formations Evaluated and Optimized by Cutting-Edge Methodology

E. Cambre, A. Abedini, X. Zhang; K. Boyle, E. Hughes

URTEC-2019-648-MS • July 2019

The objective of this paper is to present a new innovative methodology that can be used to develop and evaluate the efficacy of enhanced flowback chemistries such as a novel oil-based surface modifier. This unique chemistry has been optimized to penetrate into the nanonetwork of formations, such as the Wolfcamp, with pore throat sizes as low as 110 nm at pressure differentials of only 225 psi, thereby demonstrating the ability to increase the volume of oil recovered during flowback by 250% and increasing the average producing flowrate by 194% during testing.

Videos

Produced Water Explained - Getting it Right

As water use faces tighter restrictions in Canada and the US, the pursuit of alternative sources like high TDS groundwater or recycled produced water has become crucial.

Formation Damage Mechanisms in Unconventionals – Fluid Variables

Our innovative flowback test has provided ground breaking insights into the mechanisms of formation damage affecting the unconventional sector, and this webinar is an excellent opportunity to learn about these dynamics directly from our seasoned experts.

A new approach to optimizing completion and stimulation fluids - the component focus mistake

Every component in a completion fluid plays a role in stimulating production or protecting against risk to equipment or formation.