Why Gas Injection?

Lorem ipsum dolor sit amet, With main reservoirs being depleted over several decades of primary and secondary production stages, tertiary recovery or enhanced oil recovery (EOR) methods seem to be the most viable approach to continue producing from these reservoirs. Gas injection (for example, hydrocarbon gases, flue gases, and CO2) for EOR purposes has gained a lot of interest for its operational and environmental implications. Alleviating the climate change issues because of CO2 and hydrocarbon gas emissions has motivated the industry to consider gas injection as a promising solution to increase the hydrocarbon production while storing CO2 underground.

Swelling Test

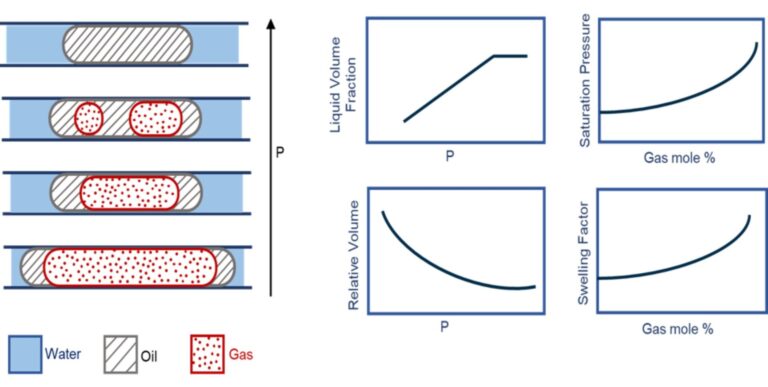

Gas injection into oil reservoirs involves complex fluid phase behavior at typically high pressure and temperature conditions. A successful implementation of such processes critically relies on accurate understanding of the relevant phase behavior and quantifying the associated fluid properties at reservoir conditions, which is further used to build and tune robust fluid models to evaluate the process performance at reservoir scales. In this regard, oil swelling test data, if measured accurately over a wide range of injection gas mole fraction, can be very instrumental to build the fluid models for gas injection processes. Swelling test data are utilized to tune and optimize an equation-of-state (EOS) model that simulates the phase behavior of injection gas and reservoir oil mixture at different mixing ratios. PVT cells are typically employed to perform the swelling test, in which the gas sample is monotonically added to the reservoir oil in the PVT cell followed by a CCE process for each mixture. While equilibrium volumetric data and fluid properties can be obtained, swelling test with PVT cell is a time-consuming, and in some cases, is a challenging process. The process can become further complicated if a wide range of gas mole fraction is selected to measure the swelling data and determine the turning point at which the nature of the single-phase gas-oil mixture changes from an oil behavior to a retrograde gas condensate one.

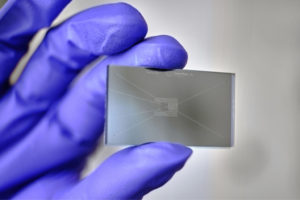

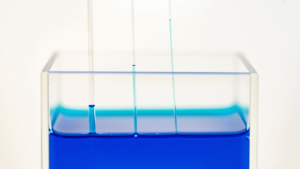

Interface On-Chip Swelling:

Interface has developed a novel microfluidics-based method to perform the oil swelling test at high pressure and temperature conditions relevant to reservoirs. This approach can provide reliable data over a wide range of injection gas mole fractions, that can cover both oil and retrograde gas condensate behaviors of gas-oil mixture. The method just uses less than 10 mL of live oil sample to generate a rich oil swelling data set in a few days – in stark contrast with conventional methods in the industry.

Sample Measurements

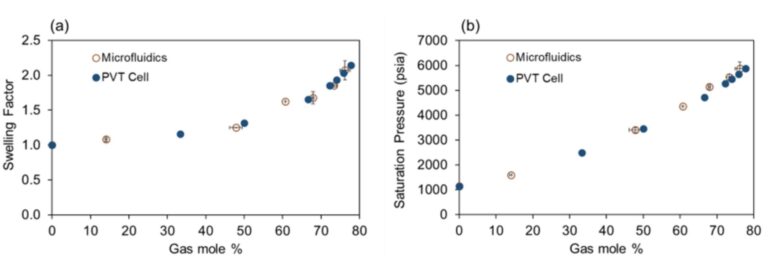

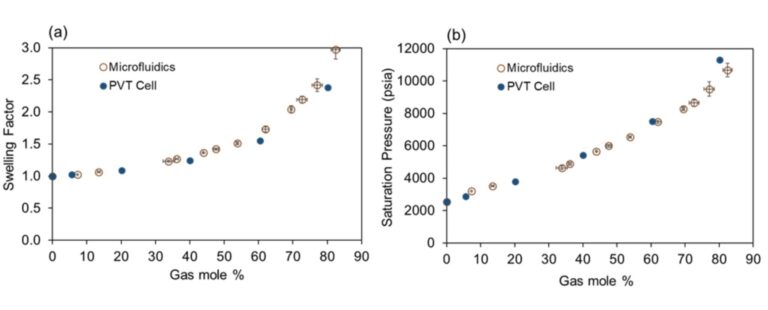

Here we show a comparison of microfluidic swelling data with those obtained by the PVT cell for two distinct oil-gas pairs. For both oil cases, there is a strong match between the microfluidics data and those obtained from PVT cell for both swelling factor and saturation pressure measurements – with ~5% deviation from the PVT cell.

Figure 1. (a) Swelling factor vs. gas mole percentage; and (b) saturation pressure vs. gas mole percentage for the first oil-gas pair (SPE-218253-MS).

Figure 2. (a) Swelling factor vs. gas mole percentage; and (b) saturation pressure vs. gas mole percentage for the second oil-gas pair (SPE-218253-MS).

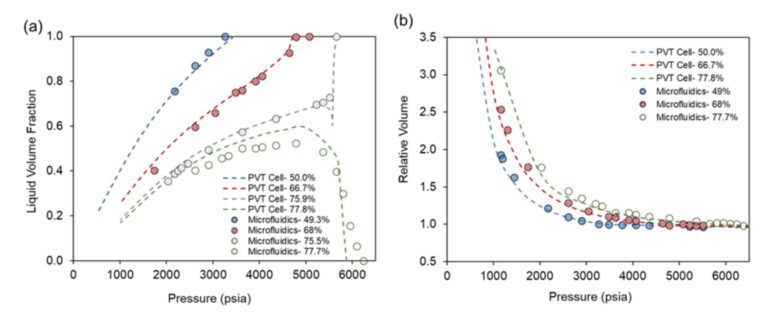

The optical access to both gas and oil slugs’ volume throughout the process enables calculation of other parameters including liquid volume and relative volume at each pressure.

Figure 3. (a) Liquid volume fraction; and (b) Relative volume obtained by the microfluidic for the first oil-gas pair (SPE-218253-MS).

Concluding Remarks:

In summary, Interface’s HPHT microfluidic technology enables performing the swelling test and quantifying the saturation pressure, swelling factor, and relevant volumetric data. The microfluidic method is also capable of reliably producing swelling data over a wide range of injection gas amount and simulating both oil and retrograde gas condensate behavior of the gas-oil mixtures. With a small fluid sample volume used here, this method uniquely provides rapid measurement and high-resolution quantification compared with the conventional PVT cell apparatus. This method can also be used for on-chip oil and gas recombination to measure the volumetric data and fluid properties. A direct application can be for unconventional resources where obtaining a representative down-hole fluid samples is practically challenging, and the solution GOR of the reservoir oil is not well determined.

Written by

Ali Abedini

Executive Vice President of Operations at Interface Fluidics