Flowback

Fracturing Fluid Optimization

Make better cost-saving completions decisions that help increase hydrocarbon recovery and reduce fracturing fluid costs. Interface’s flowback fluids screening enables you to optimize your fracturing fluids spend and avoid fluid dosing and combinations that can damage your reservoir.

Interface Fluidics helps you evaluate a range of down-hole chemicals using your specific reservoir characteristics and fluids to identify top performing additives, allowing you to make faster, data-driven decisions.

Publications

Novel Oil Flow Enhancement Chemistry for Unconventional Formations Evaluated and Optimized by Cutting-Edge Methodology

E. Cambre, A. Abedini, X. Zhang; K. Boyle, E. Hughes

URTEC-2019-648-MS

A B S T R A C T

The objective of this paper is to present a new innovative methodology that can be used to develop and evaluate the efficacy of enhanced flowback chemistries such as a novel oil-based surface modifier. This unique chemistry has been optimized to penetrate into the nanonetwork of formations, such as the Wolfcamp, with pore throat sizes as low as 110 nm at pressure differentials of only 225 psi, thereby demonstrating the ability to increase the volume of oil recovered during flowback by 250% and increasing the average producing flowrate by 194% during testing.

Nanofluidic Analysis of Flowback Enhancers for the Permian Basin:Unconventional Method for Unconventional Rock

Harvey Quintero, ChemTerra Innovation; Ali Abedini, Interface Fluidics Limited; Mike Mattucci and Bill O’Neil,ChemTerra Innovation; Raphael Wust, AGAT Laboratories; Robert Hawkes, Trican Well Service LTD; Thomas De Hass and Am Toor, Interface Fluidics Limited

SPE-195880-MS

A B S T R A C T

For optimizing and enhancing hydrocarbon recovery from unconventional plays, the technological race is currently focused on development and production of state-of-the-art surfactants that reduce inter facial tension to mitigate obstructive capilary forces and thus increase the relative permeability to hydrocarbon(kro). This study provides insight into the pore-scale evaluation of the latest flowback enhancer technologies currently applied in the Permian Basin, Texas, USA. A multidisciplinary approach, including concepts o fnanotechnology, was used to assess fluid-fluid and rock-fluid interactions occurring at the nanopore scale and their implications on enhancing oil recovery.

Reservoir-on-a-Chip Technology Opens a New Window Into Oilfield Chemistry

Trent Jacobs

Journal of Petroleum Technology, December 31, 2018

A B S T R A C T

An oil and gas startup has attracted the business with a major operator thanks to its ability to forecast whether production-enhancing chemicals will work as advertised.

Case Studies

Rapid Evaluation of Stimulation Fluids Performance on Reservoir Analogues

Microfluidics – when adapted for oil and gas – is a technology that helps the energy industry evaluate an array of stimulation products and their compatibility with individual reservoirs for specific applications down-hole.

This paper outlines the benefits of microfluidics analysis, how a large multinational operator applied it, and how it impacted decisions being made in the field.

Traditional lab testing employed for evaluating stimulation fluids can take months in a tight shale core and poses limitations to repeatability and the understanding of why a fluid behaves a certain way. The technology evaluated in this testing allows for a rapid, visual understanding of the fluid-fluid interaction under reservoir representative conditions, allowing for quick data-driven decision making.

Brochures

Fracturing Fluid Performance Screening

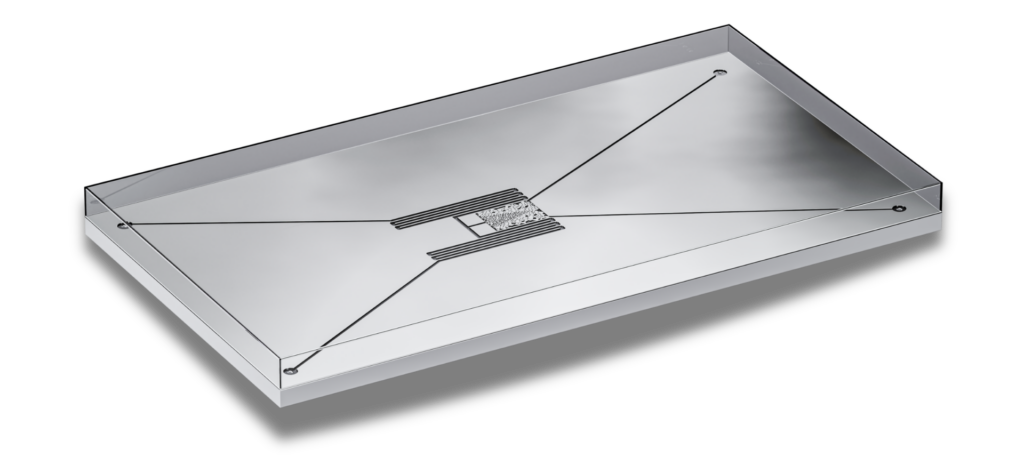

Interface’s nanotechnology platform helps operators realize additional recovery by optimizing fluid performance. The platform identifies top fluid additives, quantifying their relative performance and compatibility with other fluids, for increased confidence in completions decisions.

Interface’s physical reservoir analogs are used in place of core, on the platform. These analogs are representative of the reservoir’s geology and saturated with each wells oil and water. Our fabrication process enables a wide range of geometries and pore networks to be replicated with precision to sub-50 nm pore size. To capture the surface properties of the reservoir material, system wettability is modified in 10° contact angle increments to achieve oil-wet, mixed-wet, and water-wet systems.

In addition to representative porous media, all testing is run at reservoir temperature, pressure, and fluid flow rates. The platform’s measurements are precise due to the high level of system control, a well-documented advantage of nanofluidic systems.

A window into your reservoir

Your fluids matter. We expose fluid behaviour, quantify effectiveness, demystify mechanisms and increase both economic and environmental performance of reservoirs. Shine a light on your fluid dynamics. We’ll bring precision to your fluid injection decisions and savings and sustainability to your operations.