Comfort exists in absolutes. For example, if you were renovating your kitchen, you might feel better if a contractor gave you an exact quote to redo your cabinets, rather than an estimate. Exact values like this provide us with a sense of security. And whether you’re debating granite vs. laminate or the parameters for a highly controlled process, it’s unlikely you’d prefer a ballpark estimate over a definite number.

Microfluidic devices can offer precise values to the operators of highly controlled processes like enhanced oil recovery (EOR). Recently, EOR has garnered attention by opening the door to cleaner, more cost-effective energy extraction through the injection and permanent storage of greenhouse gases such as CO2. Which is definitely something worth paying attention to. However, current EOR processes rely on methods like the slim-tube test. These tests do a good job of characterizing critical parameters for gas injection such as Minimum Miscibility Pressure (MMP), but are expensive, require large volume of sample and are time consuming.

MMP refers to the lowest pressure where dynamic miscibility can be developed in a gas-oil system at reservoir temperature[1], when gas is flooding a reservoir. The MMP of the injected gas must be lower than the reservoir pressure to ensure that miscible displacement occurs, improving overall recovery[2].

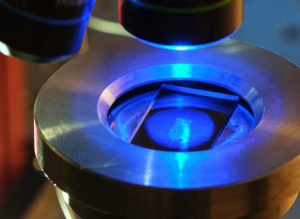

Interface Fluidics has created a novel microfluidic chip capable of measuring MMPs of gas-oil systems with greater precision and confidence than the standard slim-tube method, which lacks standardized parameters generating varied results[3]. While the slim-tube apparatus estimates MMP by constructing a linear regression around a few critical data points, Interface’s analogue uses a data-driven approach to yield results with greater accuracy. Right now, each chip run collects anywhere from 25 to 75 values per gas-oil system, resulting in high-resolution data plots that operators can use to determine MMP directly[2].

By miniaturizing the slim-tube method via microfluidic technology, Interface Fluidics has generated a more rapid and cost-efficient determination of MMP through the use of significantly smaller sample volumes to conduct initial tests. This, in turn, allows operators to analyze several reservoirs or blocks of variation within the site for changes in MMP. As changes in oil and gas composition can dramatically impact MMP values, accurately capturing this variable lends to higher accuracy and reliability in reservoir simulation models – and more detailed planning of miscible gas flooding processes.

By decreasing end-user cost for miscibility measurements, Interface also enables the feasibility of minimum miscibility enrichment (MME) studies, which allows operators in optimizing their gas injection strategy. Acquisition of lower sample volumes has also correlated to decreasing the economic burden and health/environmental risks associated with sampling from wells and open hole formations.

Overall, by employing microfluidic technology, Interface Fluidics enables operators and companies to access more reliable MMP values at a lower risk, with lower operational and environmental costs by requiring smaller samples. The imminent business potential of microfluidic-based testing is accentuated by the platform’s excellent reliability, lower price and quick turnaround time when compared to conventional methods. Now, imagine how nice it would be if you could get the same reliability from your average kitchen contractor?

Learn more with this paper written by Interface’s Ali Abedini and Sourabh Ahitan, in partnership with Equinor.

[1] Whitson, C. H., & Brule, M. R. (2000). Phase behaviour. Richardson, Texas: Vol. 20, i PHASE BEHAVIOR Curtis H. Whitson Professor of Petroleum Engineering U.Trondheim, NT Hand Founder PERA a/s and Michael R. Brulé President and Chief Executive Officer Technomation Systems Inc. First Printing. Henry L. Doherty Memorial Fund of AIMES.

[2] Unger, F., Ahitan, S., Yang, T., Worthing, S., Abedini, A., Uleberg, K. (2021). A New Fluidics Method to Determine Minimum Miscibility Pressure. 21st European Improved Oil Recovery Symposium, Vienna, Austria, April 19–22.

[3] Elsharkawy, A. M., Poettmann, F. H., & Christiansen, R. L. (1992). Measuring Minimum Miscibility Pressure: Slim-Tube or Rising-Bubble Method? SPE/DOE Enhanced Oil Recovery Symposium. doi: https://doi.org/10.2118/24114-MS