De-risk Your Reservoir Like Never Before

Optimize in the unconventional space with our completions, regain conductivity, flow assurance and SAGD tests.

There's just too many variables...

We deal with operators in the oil and gas industry who want to narrow down different variables of risk, optimize their current processes, and get data they need.

- Mitigate formation damage

- Reduce flow assurance issues

- Optical chemical spend

- Understand how different variables impact oil recovery

Who is Interface Fluidics

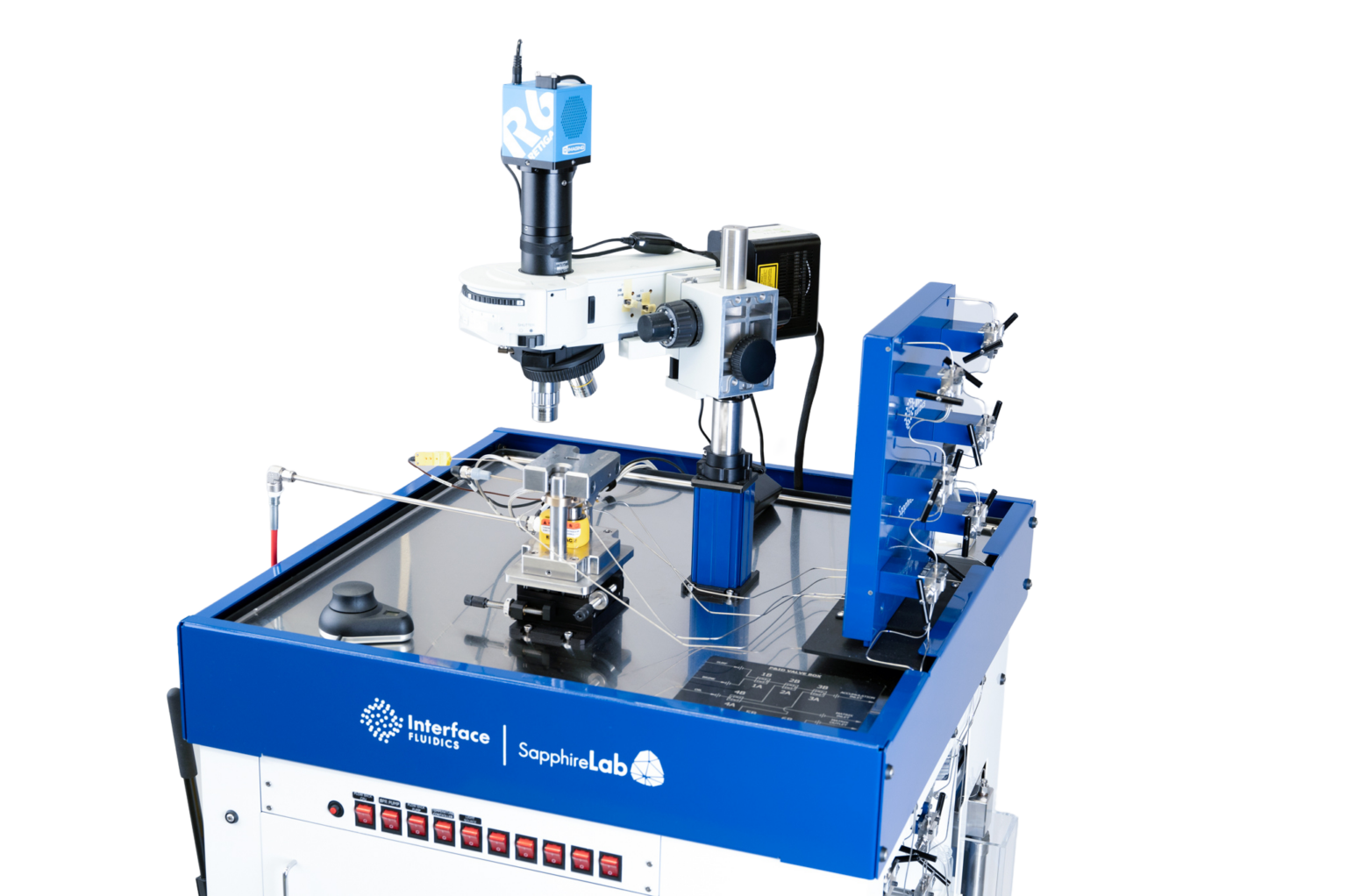

Alberta-based oilfield lab service company with a proprietary nanotechnology platform that uses microfluidics to evaluate downhole fluid performance under relevant reservoir conditions. Specializing in flowback aid and enhanced oil recovery fluid evaluation with fast and repeatable tests with pore-scale optical access.

Our testing technology shows you how fluids behave at the pore scale and provides critical phase behaviour information for building computer reservoir models. Interface solutions have helped the energy industry cut chemical costs, increase ROI, and take the guesswork out of operations – smaller samples also mean less energy use and lower emissions

Repeatable

Reliable

Deeply Informative

Changing The Way You Interact With Your Fluids

Unlock superior data quality every day with our state-of-the-art turnkey microfluidic system designed for your laboratory needs. Experience unparalleled precision and efficiency in fluid analysis with our

next-generation technology.

What Our Clients Say

Trusted By Many

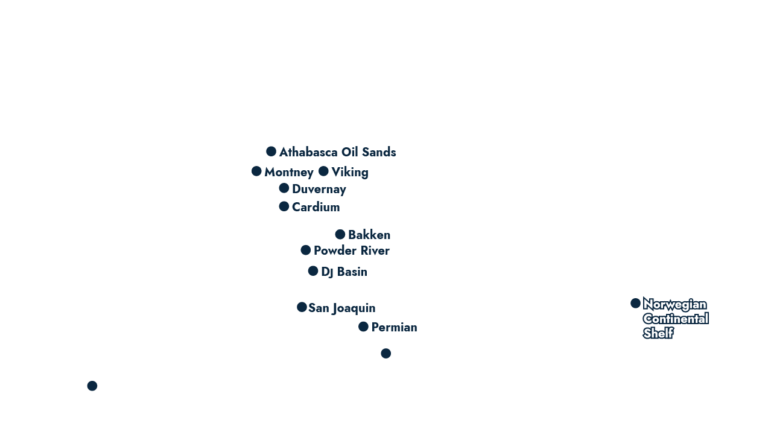

We Help Operators Solve the Most Challenging Problems

Bakken: Analyzed nano-fluids, surfactants, and displacement efficiency while measuring regain conductivity for optimized chemistries.

Athabasca Oil Sands: Quantified the performance of solvents and processes with condensate blend solvents under various reservoir conditions.

Montney: Evaluated performance additives, surfactants for water flooding, and optimized surfactant concentrations in waxy oil reservoirs.

Viking: Optimized HVFR and breaker loadings, and evaluated performance additives

Duvernay: Helped vendors understand fluid compatibility of different chemistries and water sources in an oil wet formation and optimized chemistries for oil flowback and minimized formation damage.

Powder River: Evaluated performance of nano-particle, surfactants, and HVFRs while determining least damaging fluid packages for reservoirs.

DJ Basin: Optimized chemical package for least reservoir damage and evaluated different biosurfactants and their concentrations.

Cardium: Optimized HVFR and breaker loadings, and evaluated performance additives and surfactants for water flooding applications.

San Joaquin: Optimized chemistry selection and reservoir damage mitigation to maximize oil recovery.

Permian: Evaluated breaker performance, optimized chemistry concentrations, and reduced operators' chemical spend.

Newfoundland: Measured Minimum Miscibility Pressure for various different gasses in 2-3 days only requiring 20 ml of oil.

Europe: Minimum miscibility pressures, phase trapping measurements of hydrocarbons and water,

gas condensate production strategy measurements.

Marmul, Oman: Investigated foam stability in porous media, evaluated thermal

processes and EOR additives, and analyzed surfactants to quantify

water displacement in gas reservoirs.

Eagle Ford: Evaluated optimal stimulation chemicals for hydraulic fracturing by analyzing surfactants, breakers, and HVFR with varying wettability,

evaluating surfactant performance in water-wet systems, and comparing guar-based gels to HVFRS to quantify potential reservoir damage.

A window into your reservoir

Your fluids matter. We expose fluid behaviour, quantify effectiveness, demystify mechanisms and increase both economic and environmental performance of reservoirs. Shine a light on your fluid dynamics. We’ll bring precision to your fluid injection decisions and savings and sustainability to your operations.