In 2015, I found myself standing at a crossroads, wrestling with a challenging decision. My friend Tom was trying to convince me to leave the well-trodden career path I was on at Canadian Natural Resources, and start a company to solve a problem that we were both struggling with in our day to day, rather than fix it from the inside. After 5 years, I was looking for a new challenge. Tom’s proposal was appealing yet perplexing, a fluid analysis company that uses the technology from pregnancy to do testing for oil and gas. He laid out the problem and stated, “I need a CEO,” to which I quickly retorted, “You don’t want me for that.”

Despite my initial reservations, the seed was planted. I had to ask myself, should I leave the relative security of my current position to embark on an uncertain journey into the world of engineering, microfluidics, and advising reservoir Engineers, which I am not?

However, as daunting as it seemed, it seemed like such an obvious solution to a huge problem. I felt an itch to learn more about microfluidics and its technical intricacies and tackle it head-on. It was this curiosity, coupled with a yearning for a break from the monotony of my job, that eventually pushed me to step out of my comfort zone and delve into this new world.

Tom stepped in as my guide into this new world, teaching me about reservoir engineering, microfluidics, and chemistry. He taught me over lunch three days a week for over six months, where we always circled back to one fundamental question: what was the critical gap in the reservoir engineering workflow? More importantly, would you make a different decision if you had the data we intended to provide?

in the Energy New Ventures Competition.

This critical gap stemmed from the fact that we knew operators needed data more quickly, and microfluidics could be an answer to this, looking at parallels in the biomedical space where this technology was already being applied to solve similar challenges. At oil companies, it is common to make decisions faster than data can be gathered, leading to operating within a constant sphere of uncertainty with difficult-to-interpret data points. This helped us build a stronger case that the oil and gas sector needed higher-quality fluid data that could be collected in half the time and with half the resources needed. I felt convinced that the current inability to interpret fluids in an economical and timely manner were significant problems that needed addressing.

Despite the importance of this area, I also learned it had seen little innovation over the years. Although some incremental improvements have been made, the fundamental methodologies remain the same as traditional tools used since the ’80s and before are still prevalent in the industry. Seeing an industry remain static for such a long period clearly indicated an opportunity for innovation, both in terms of product development and in the current way of thinking.

I also learned about high-risk investment scenarios, where billion-dollar investment decisions were being made with data from research of Universities. Universities have fundamentally different priorities than commercial laboratories. They need to collect data, publish papers, and then move on to the next innovation or area of study. Consistent, repeated work is antithetical to their goals.

At Interface, we have always said, The Fluids Matter. Looking back, this philosophy started with a hypothesis that Tom and I formed and that has crystallized into a hard belief. The more work we do, the more this has crystallized. We believe this because time and time again, our clients have come to us with expectations based on “known” factors, and through our testing, we found that the actual outcomes were often surprisingly different.

Each project we embarked on has underscored the importance of empirical data to inform decisions. Helping operators understand that their fluid model was paramount to the economic feasibility of their assets hinged on the properties, analysis, and interactions of fluids.

In 2023, we will have solidified that Microfluidics is a key tool for understanding various aspects of the upstream oil and gas or energy industry. Our success has come from collaborating with the right people at the right time to solve the right problem. When we develop solutions for one company, it often benefits others in the industry grappling with similar challenges. These partnerships result and new technology development, enhancing our understanding of their problems and enabling us to fine-tune our products according to a shared goal, better understanding of wells through an optimization workflow that is easy and quick.

Our unique capability to apply microfluidics to address complex problems has been instrumental in developing our technology to meet the needs of our customers and partner with companies to confront challenging problems.

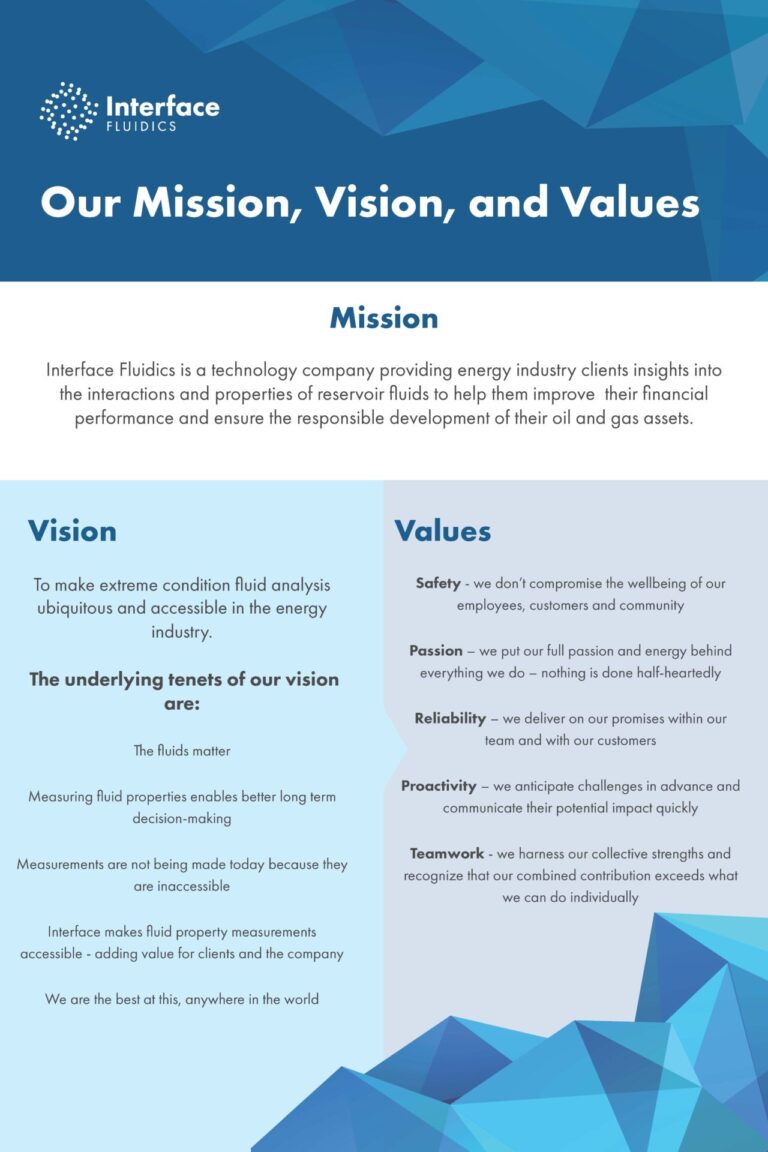

The guiding principles of Interface have always been rooted in these beliefs. Our mission continues to be to drive innovation and foster a collaborative approach to problem-solving. We aim to understand our clients’ challenges better and use that knowledge to enhance our products and the broader industry. We see ourselves as more than a service provider; we are a partner for our clients in their pursuit of improved understanding and solutions.