Subsurface Solutions

What is Happening With Your Asset

Solutions focused for Completions, Reservoir, Exploitation and Production Engineers

Chemistry

The Problem

With so many chemicals available to help mobilize trapped oil, it’s crucial to identify the best one for each specific site. However, this process can be challenging, time-consuming, and costly.

The Root Cause

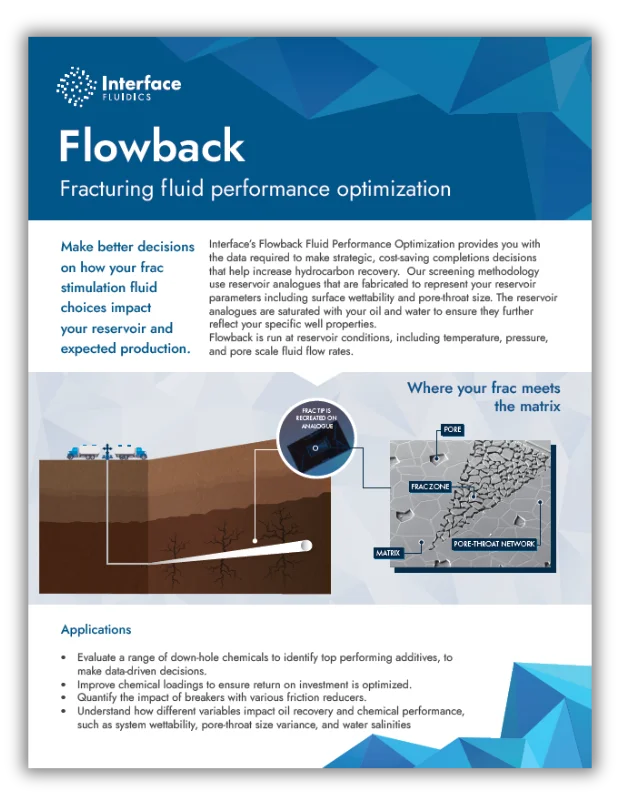

Fracturing fluids are typically evaluated using traditional laboratory methods, which are time consuming and costly. This approach makes it difficult to isolate the best mixture and to modify it based on changing site parameters.

The Solution

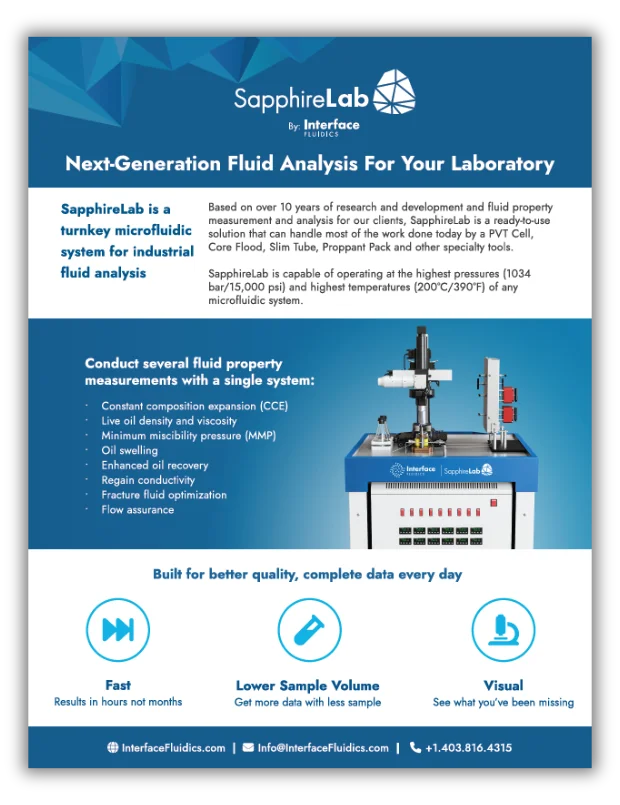

SapphireLab offers a faster and more efficient way to isolate and quantify each chemical’s effectiveness under real reservoir conditions using smaller samples. This approach helps quickly identify the optimal chemistry for maximum production.

Water

The Problem

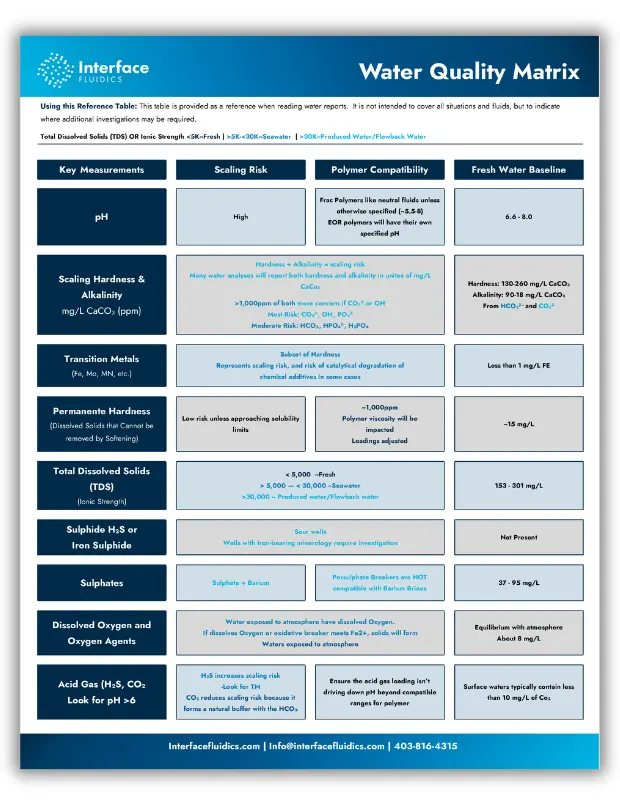

Water is the foundation for completion fluids, and without confirming how it performs in the specific waters used for a job, there’s a risk of multiple incompatibilities between the frac water, formation water, and chemical mixture. This is especially true for high TDS waters like recycled produced water.

The Root Cause

When injected water is incompatible with formation water, it can cause pore blockages due to scale buildup. Additionally, the performance of chemicals may be partially or completely compromised, depending on the water compositions.

The Solution

SapphireLab can quickly isolate and quantify water conditions in the reservoir using smaller samples. This allows for the detection of changing water conditions, ensuring maximum production.

Oil

The Problem

Maintaining oil field sites can be challenging due to the constantly changing conditions and the variety of products used. Finding the right solution for each unique well or pad is essential to maximizing production.

The Root Cause

Every well and pad has its own set of characteristics, requiring tailored solutions to optimize performance. Traditional methods often struggle to account for these variations, leading to less effective outcomes.

The Solution

EOR

The Problem

Mature oil fields come with unique challenges when it comes to finding the most cost-effective extraction methods, and the later stages of these fields can often make decision-making even tougher.

The Root Cause

As oil fields mature, they typically face pressure-depleted reservoirs, complex flow regimes, and continually changing subsurface conditions. These factors make it difficult to predict and manage production efficiently.

The Solution

SapphireLab designs and uses custom chips for testing that accurately replicate changing reservoir conditions. This advanced approach allows for precise predictions of incremental oil and water rates, helping operators make more informed decisions about field management.

Water Flood

The Problem

The cost of operating and managing water treatment and purification plants can be a significant burden on your budget.

The Root Cause

Fluctuating water sources and changes in produced water over time can lead to costly fixes and mitigation efforts, which can impact injectivity and overall efficiency.

The Solution

SapphireLab is equipped with custom chips that monitor changing site conditions in real time. It can be installed on-site, allowing for flexible testing with or without chemistry whenever and wherever it’s needed most.

PVT

The Problem

Traditional PVT (Pressure-Volume-Temperature) testing often faces bottlenecks, leading to delays and inconsistent results.

The Root Cause

These tests require large sample sizes to ensure reliable data, and processing these samples into usable results takes time. This lengthy process can reduce the repeatability of tests, making it difficult to adapt quickly to changing reservoir conditions.

The Solution

SapphireLab requires significantly smaller sample sizes—up to 100 times less—to deliver repeatable and highly reliable visual results. Testing can be conducted either onsite with an installed SapphireLab or through Interface Fluidics. This approach improves measurement resolution while maintaining the accuracy and consistency of traditional PVT methods.

Chemical Performance

The Problem

With so many chemicals available to mobilize trapped oil, it’s crucial to identify the best one for each specific site to maximize efficiency and production.

The Root Cause

Traditional laboratory methods for evaluating fracturing fluids are often slow and expensive. This makes it challenging to isolate the optimal chemical mixture and adapt it to the changing conditions of a site.

The Solution

SapphireLab can quickly isolate and quantify each chemical under real reservoir conditions using smaller samples. This streamlined approach helps identify the optimal chemistry for maximum production, saving both time and cost.

Foundation Damage

The Problem

Injection or flowback damage can cause problems that slow down and increase the cost of recovery. Tackling these issues quickly and effectively is key to minimizing their impact and keeping the recovery process efficient and cost-effective.

The Root Cause

During the fracturing process, substances like scale, wax, asphaltenes, or emulsions can form. These issues can reduce the efficiency of the fracturing process, increase maintenance needs, and drive up operational costs.

The Solution