From the beginning, Interface Fluidics has been working to bring innovative, efficient technology solutions to the oil and gas industry. Even passing conversations about a client need can lead to breakthrough research, as was the case with regain conductivity. Initially, our client was looking for a way to alleviate the concerns of traditional regain conductivity testing: the high costs, the slow turnaround times and the lack of test repeatability.

The market for regain conductivity shows that the traditional methods leave a lot of room for improvement. So in November 2020, we began working to develop a better method that could help mitigate some of these issues – and just a few months later, we’ve been able to show that improvement is possible.

Because Interface uses an identical reservoir analogue, each test is comparable to each other, even years apart. This gives us the unique opportunity to create a worldwide data base comparing chemicals directly against each other based on regain conductivity testing.

As we are able to conduct more screening from areas around the world, we’ll be able to make better recommendations based on the available data, thus providing even more value to customers. Collaboration with regions around the world will allow for more innovation and accessibility.

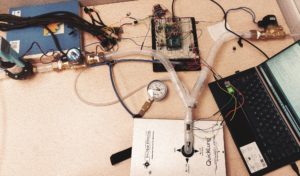

For current methods, variation in repeatability and reproduction can vary by as much as 80% from test to test.1 Interface has been able to produce reservoir analogues that are identical to each other for testing and mimic the rock formation the customer will be fracturing. Using these devices means that there are no issues surrounding packing, which is a large concern in the conventional method. There is no channeling and these devices have a permeability as low as 1 Darcy, which will provide greater differentiation in fracking fluid performance. Additionally, the turnaround time is now hours instead of days.

The results obtained from regain conductivity testing can also be compared with shale performance in Interface’s flowback protocol. Find out more about this advance in regain conductivity technology with our latest case study.

[1] K. Blair, “MODIFYING FRACTURE CONDUCTIVITY TESTING PROCEDURES,” Montana Tech, 2015. https://core.ac.uk/download/pdf/48315842.pdf