Flowback

The Standard in Fracturing Fluid Optimization

The Challenge

Fluid compatibility is the difference between high performing wells and major production issues. Even if your chemistry doesn’t change well to well, your water and oil does. Getting the fluids and their doses right is critical for success, and traditional fluid analysis for tight shale has several challenges, including:

- Speed: Amott Cell tests can take weeks to months

- Consistency: Variations between shale cores makes fluid comparisons unreliable

- Accuracy: Core flood setups struggle with low-effluent conditions, making testing cumbersome and prone to error

The Breakthrough

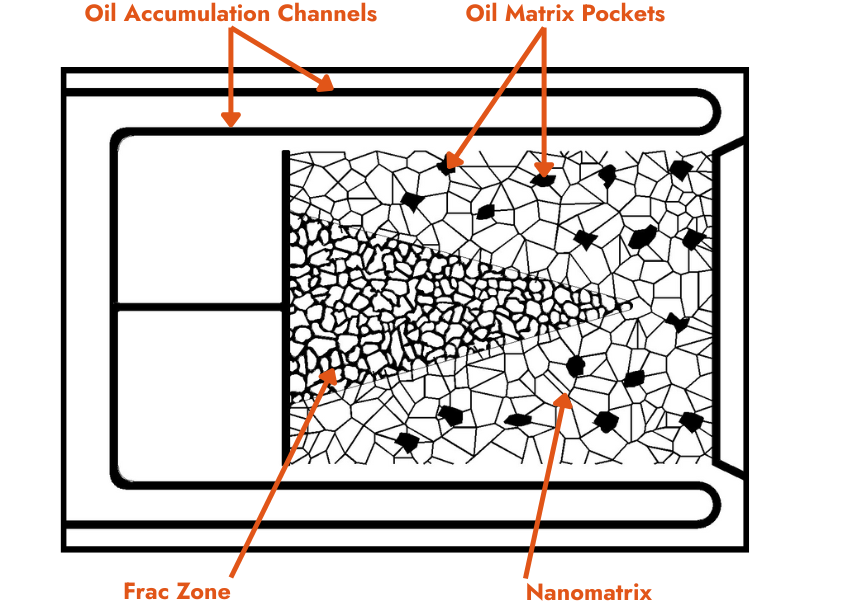

Chip Dimensions: 38 x 21 x 2.75 mm

Click to view video of Flowback and Fluid Optimization

The SapphireLab Flowback test is a fast, standardized way to screen individual chemistries or full frac fluid packages.

Compatibility testing with the SapphireLab Flowback test can predict, prevent, and remediate the most common issues (like scales or emulsions), bringing more productive wells online with fewer startup and production challenges.

In a single run, it identifies potential compatibility issues, measures hydrocarbon production, and visualizes formation damage, all using consistent porous media for reliable comparisons.

With results in under a day, you can rapidly test, iterate, and optimize fluid packages with confidence.

Who Uses The SapphireLab Flowback Test

Prevent Overspending on Chemistry

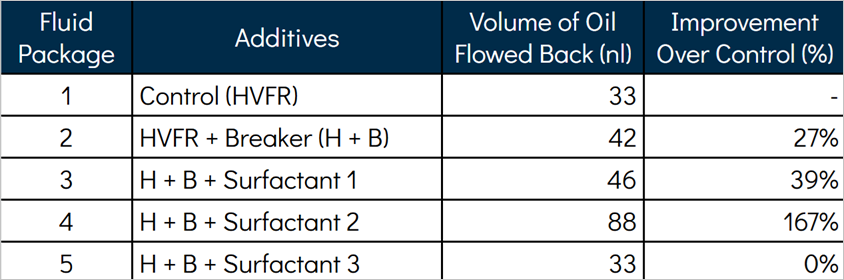

When it comes to surfactants and flowback aids, using more than the optimal dosage can diminish the ability of oil to flow from formations. In addition to selecting the correct concentration of a flowback aid, the SapphireLab Flowback test can provide insight into the fluids package to ensure that there are no chemical-chemical or chemical-water incompatibilities by testing whole fluid systems, in addition to testing components in isolation.

Reduce Formation Damage

The SapphireLab Flowback test’s unique rapid chemical screening capabilities enables Completion Engineering teams in unconventional production to optimize hydraulic fracturing fluid packages for reducing formation damage. Through fine tuned control of oils, surfactants, polymers, water sources and more, at extreme conditions, teams can trial different chemistries and concentrations at low cost and zero risk, to identify the best performing fluid packages. If desired, teams can then test the best performing fluid package in a core flood to validate results and measure the impact of rock-fluid interactions, before moving to the well. Reducing formation damage results in better performing wells.

Optimize Fluid Packages for Customer Projects

Because we can accurately manufacture many microfluidic chips with the same specifications, and the SapphireLab Flowback test can typically be performed in a day, it is both convenient and possible to screen frac fluid packages to pick the best performer for a given reservoir.

Accelerate New Product Development

The development and fine tuning of new chemical formulations takes time, some trial and error, and deep insight into fluid compatibility and behavior. The inherent speed and repeatability of the Flowback test makes it a perfect match for experimentation and fluid formulation development, for quick turnarounds.

Gain Competitive Advantage

Gain a competitive advantage by clearly demonstrating to your customers the effectiveness of your chemistries in combination with other injected and reservoir fluids.

Accelerate Project Delivery

With a SapphireLab Flowback test being completed in about a day, there is a significant potential to accelerate/optimize timelines for routine tests like screening fluids, core floods, or longer-term research and development fluid projects. Due to its high throughput and low requirement on resources, the SapphireLab Flowback test can be used as a pre-core flood fluid screening tool, making better use of valuable core and fluid samples.

Add New Capabilities

The SapphireLab Flowback test offers Service teams a new tool to rapidly screen fluids for customer projects. This test can be a precursor test to traditional core floods, or stand alone by enabling comparisons of full frac fluid packages never before possible.

Comparison With Traditional Test Methods

| SapphireLab Flowback Test | Proppant Pack | Core Flood | Amott Cell | |

| Can predict the relative performance of volume of oil flowed back | ||||

| Conducted at high pressure and high temperature | ||||

| Does not require cuttings or core | ||||

| Can be run in a day | ||||

| Tests use consistent porous media | ||||

| Enables visualization of formation damage and pore scale fluid flow | ||||

| Designed for low fluid flow rates and volumes |

How it Works

Overview

The SapphireLab Flowback test uses microfluidics technology to help you analyze fluid interactions at high pressure and high temperature conditions at the micro and nano scale. Interface Fluidics has leveraged over 15 years of experience and innovation in microfluidic research and development, to produce this standardized test. Since initial development, Interface Fluidics and its customers have successfully ran thousands of Flowback tests, helping producers increase hydrocarbon production, lower fluids expenses and reduce formation damage.

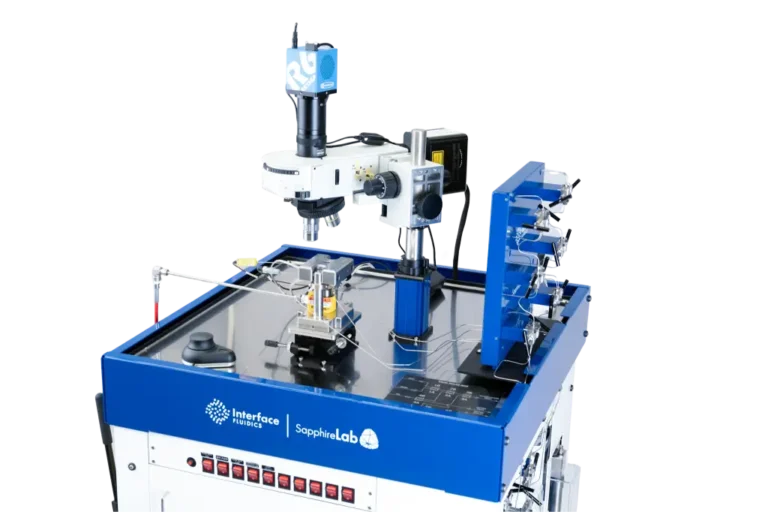

Conducting a Flowback test requires several key components, and can be completed in our laboratory or in your laboratory by purchasing our turnkey SapphireLab system.

The Flowback S100 Microfluidic Chip

The Flowback S100 microfluidic chip uses two etch depths and is designed to represent the pore geometries of tight formations during hydraulic fracturing, and includes four inlets/outlets, a high permeability frac zone, a surrounding nanomatrix (with oil pockets) and oil accumulation channels. This chip is the heartbeat of the SapphireLab Flowback test.

Step 1: Insert chip into SapphireLab

The microfluidic chip is inserted into the SapphireLab chip holder. The onboard software is used to set the temperature of the different zones, the pressure drop across the chip, and to watch the on-chip fluid interactions live. The software automatically takes images of the chip in each step and saves them for analysis.

Step 2: Prepare microfluidic chip

Reservoir fluids such as oil and formation water are injected into the microfluidic chip and aged with heat as needed to match the wettability of your reservoir. In some instances ageing may take place off chip. SapphireLab’s image analysis software is used to confirm the desired wettability has been achieved.

Step 3: Inject Frac Fluid Package

The frac fluid package (surfactants, friction reducers, produced/fresh water, biocides, breakers, etc.) is injected into the chip, displacing the initial oil and formation water.

The SapphireLab image analysis software is used to measure Oil Displacement (%) during the injection.

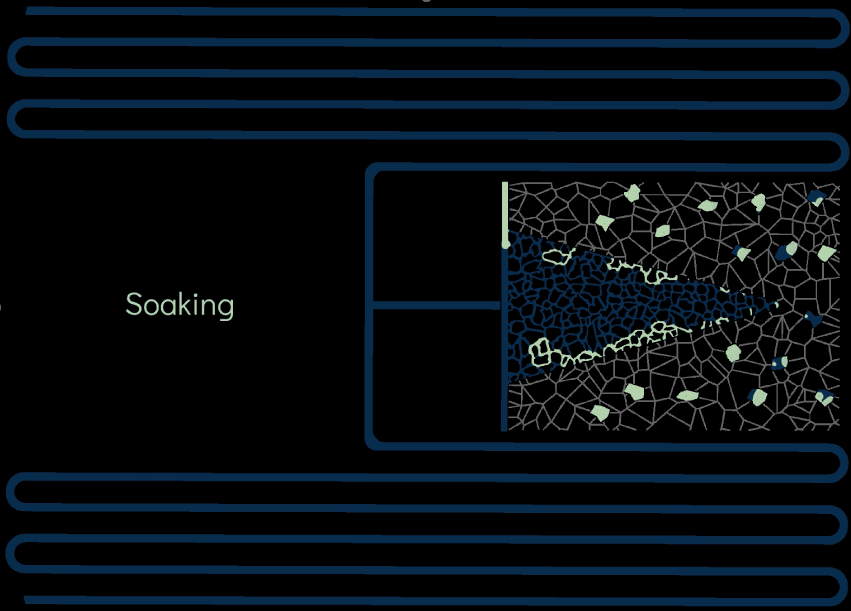

Step 4: Soak

The frac fluid package is left to soak for 1 to 2 hours.

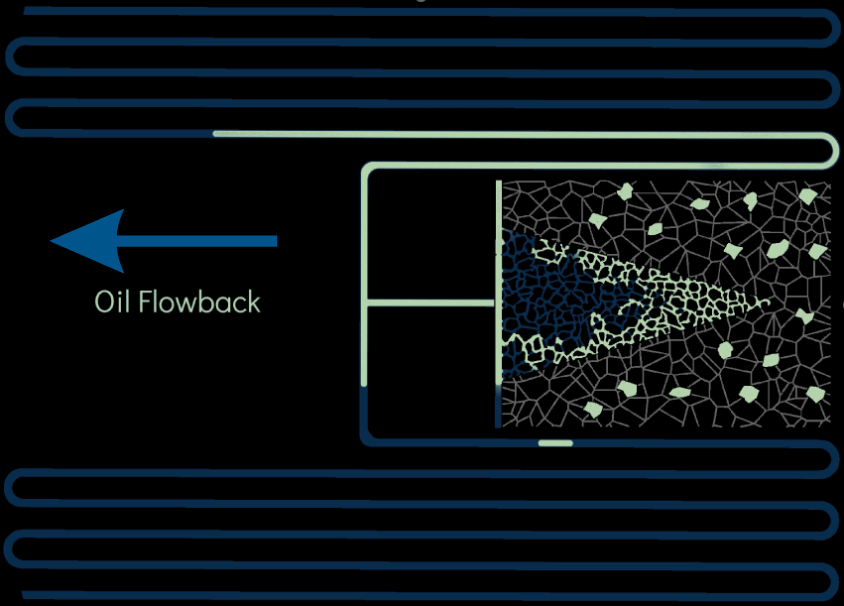

Step 5: Flow Oil Back

Oil is flowed back in the opposite direction as the initial injection, from the nanomatrix, through the frac zone and into the accumulation channels at the top and bottom of the chip (2 hrs).

The SapphireLab image analysis software measures the Regain Saturation During Flowback (%) and the Volume of Oil Flowed Back (nl).

Step 6: Compare Frac Fluid Package Performance

After several different runs, a comparison can be made to determine the effectiveness of each frac fluid package to a control.

In addition to performance metrics, the test enables visualization of the mechanism of formation damage (e.g. emulsions or scales).

Additional Resources

Rapid Evaluation of Stimulation Fluids Performance on Reservoir Analogues

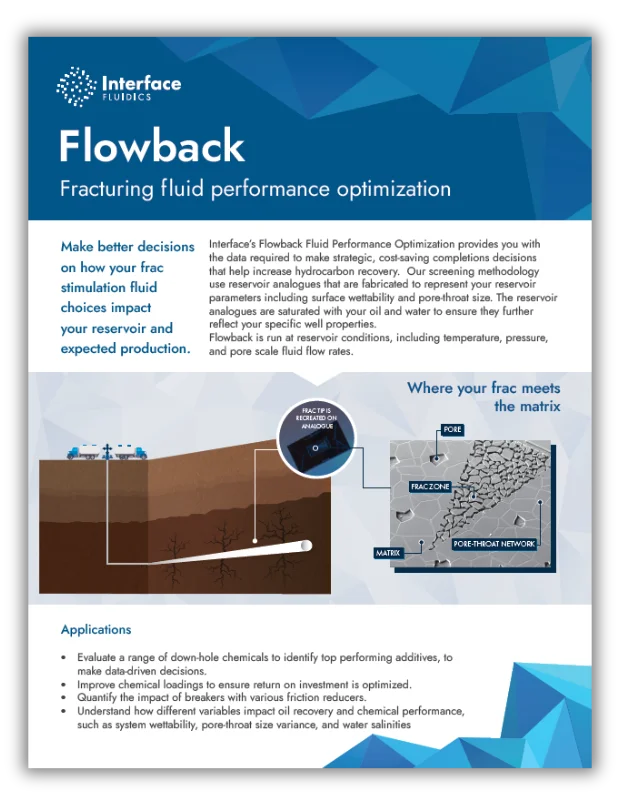

Microfluidics – when adapted for oil and gas – is a technology that helps the energy industry evaluate an array of stimulation products and their compatibility with individual reservoirs for specific applications down-hole.

This paper outlines the benefits of microfluidics analysis, how a large multinational operator applied it, and how it impacted decisions being made in the field.

Traditional lab testing employed for evaluating stimulation fluids can take months in a tight shale core and poses limitations to repeatability and the understanding of why a fluid behaves a certain way. The technology evaluated in this testing allows for a rapid, visual understanding of the fluid-fluid interaction under reservoir representative conditions, allowing for quick data-driven decision making.

Fracturing Fluid Performance Screening

Interface’s nanotechnology platform helps operators realize additional recovery by optimizing fluid performance. The platform identifies top fluid additives, quantifying their relative performance and compatibility with other fluids, for increased confidence in completions decisions.

Interface’s physical reservoir analogs are used in place of core, on the platform. These analogs are representative of the reservoir’s geology and saturated with each wells oil and water. Our fabrication process enables a wide range of geometries and pore networks to be replicated with precision to sub-50 nm pore size. To capture the surface properties of the reservoir material, system wettability is modified in 10° contact angle increments to achieve oil-wet, mixed-wet, and water-wet systems.

In addition to representative porous media, all testing is run at reservoir temperature, pressure, and fluid flow rates. The platform’s measurements are precise due to the high level of system control, a well-documented advantage of nanofluidic systems.

Novel Oil Flow Enhancement Chemistry for Unconventional Formations Evaluated and Optimized by Cutting-Edge Methodology

E. Cambre, A. Abedini, X. Zhang; K. Boyle, E. Hughes

URTEC-2019-648-MS

Novel Oil Flow Enhancement Chemistry for Unconventional Formations Evaluated and Optimized by Cutting-Edge Methodology

Harvey Quintero, ChemTerra Innovation; Ali Abedini, Interface Fluidics Limited; Mike Mattucci and Bill O’Neil,ChemTerra Innovation; Raphael Wust, AGAT Laboratories; Robert Hawkes, Trican Well Service LTD; Thomas De Hass and Am Toor, Interface Fluidics Limited

SPE-195880-MS

Novel Oil Flow Enhancement Chemistry for Unconventional Formations Evaluated and Optimized by Cutting-Edge Methodology

Trent Jacobs

Journal of Petroleum Technology, December 31, 2018

Produced Water Explained - Getting it Right

As water use faces tighter restrictions in Canada and the US, the pursuit of alternative sources like high TDS groundwater or recycled produced water has become crucial. But this shift brings its own set of questions. Why is produced water a complex choice for fracing? What critical questions should you ask your suppliers if you’re considering or already using produced water? Is it true that opting for produced water means higher chemical costs? How can you find the right frac chemistry that aligns with these alternative water sources? And, do Cationic FRs hold the key to solving these issues?

Read MoreLess

Watch our webinar, where we don’t just pose these questions—we dive deep to offer insights and actionable solutions. We’re here to cut through the ambiguity, providing clarity and confidence for everyone involved, from corporate executives to completions engineers on the frontline. Interface is dedicated to partnering with you to navigate the intricate world of water management in fracing, emphasizing efficiency, cost reduction, and data-driven decisions over marketing hype.

Original Air Date: March 21 2024

Formation Damage Mechanisms in Unconventionals – Fluid Variables

Fluids can damage your formation. Are you curious about the challenges presented by formation damage in unconventional formations? Delve into the complexities of subsurface dynamics in tight porous media, which is a critical yet challenging aspect of unconventional oil recovery.

Our innovative flowback test has provided ground breaking insights into the mechanisms of formation damage affecting the unconventional sector, and this webinar is an excellent opportunity to learn about these dynamics directly from our seasoned experts.

Original Air Date: July 18 2024

A new approach to optimizing completion and stimulation fluids - the component focus mistake

Every component in a completion fluid plays a role in stimulating production or protecting against risk to equipment or formation. At Interface, we’ve observed that all additives can impact the most important parameter, how much oil you can get out of the producing formation. Often, additives not intended for use as stimulation chemicals – but rather for some other purpose such as inhibiting corrosion – can interfere with the selected stimulation additives, resulting in diminished return on investment.